X-FAB : Replacement of two extractor fans

Project duration : 2 days

Technicians : 2

Client expectation

X-FAB (Corbeil-Essonnes) specializes in advanced technologies for the processing of analogue and mixed signals The company produces electronic components varying from 1.0 to 0.13 micrometers using advanced modular processes.

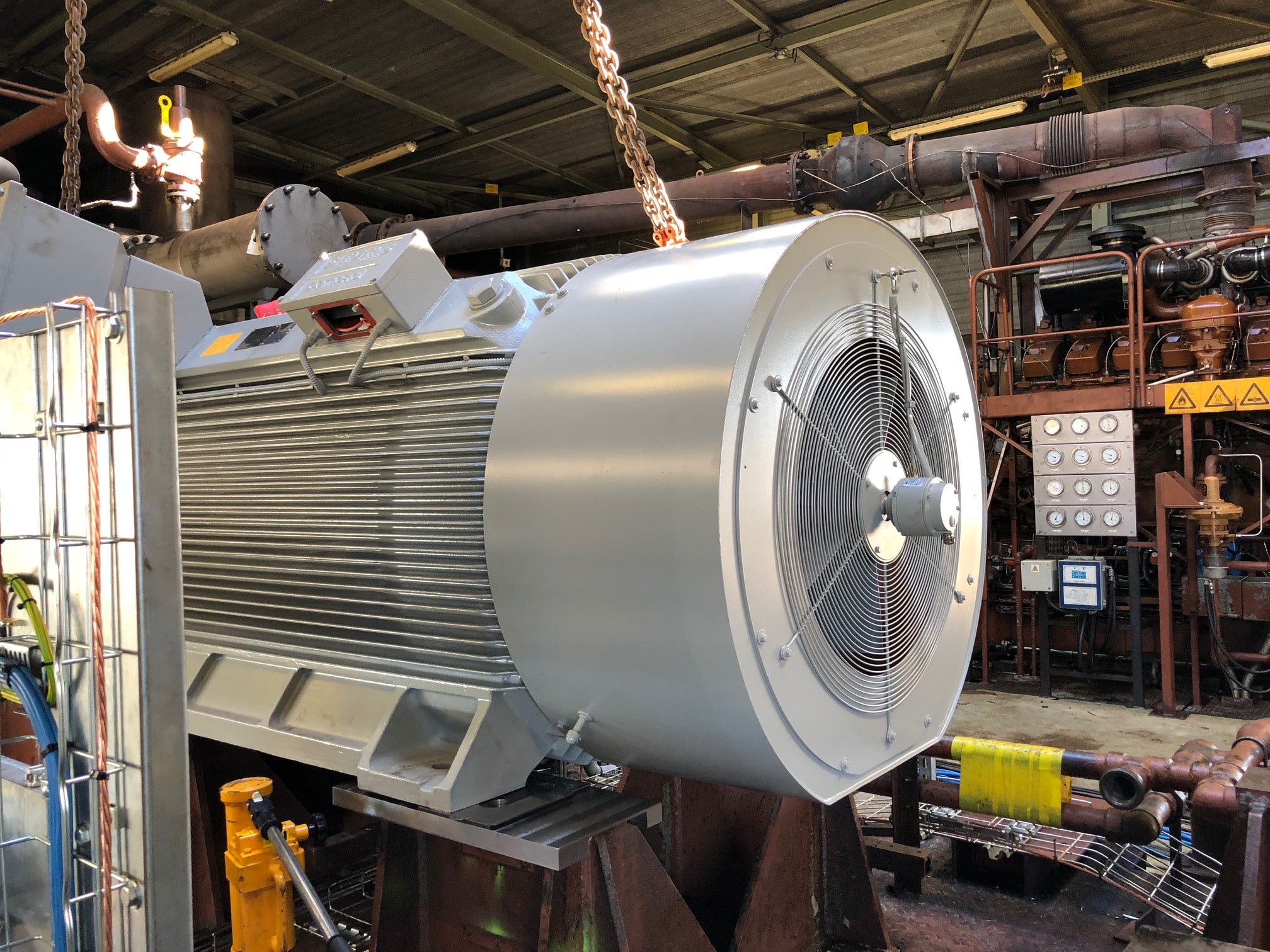

The company has two extractor fans (AV3 / LN355LL 82 – 400 kW) which need to be replaced. One of them is actually broken and the second refurbished. For this purpose, X-FAB has asked us to remove and refit the products.

DV GROUP Solution

The extractors fans allow for operation of a functional circuit in the building’s clean room. They prevent impurities from entering the room, thus allowing it to be sterile.

The fans are positioned on the roof of the building, so a suitable solution must be found for their safe removal. There are two possible options:

- The installation of a giant crane with a 40m jib.

- The use of an AS 350 Squirrel helicopter

We decided to choose the helicopter because the solution is more economical and quicker.

The removal of the extractor fans is done in several stages:

- Motor disconnection (Omec: OMT1 IE2 25 M4 and ALMO (Sermes motorization): SM3 225 MC4 LL NS PTC)

- Dismantling the cable channel

- Disconnecting the extractor ventilator flanges (chimney side)

- Disconnecting the suction flange from the extractor fan

- Replacing the shock absorbers

- Replacement of the 2 extractor fans with a new fan and a refurbished one that the company has in stock

After removal, the extractors fans were taken for subsequent inspection in our workshops.

Clients gains and benefits

- Production downtime was reduced through the use of the helicopter

- Economic gain: 50% savings compared to the installation of the crane

Expertise

We provide you with engineering, maintenance and control solutions based on our knowledge of your processes.

Case studies

You may also be interested in

Vibration monitoring of a coffee production line

Obsolescence Management: Audit of a Truck Engine Factory’s Equipment Fleet

Repair and reliability of drives

ELOPAK: Corrective preventive electronic maintenance

Preventive maintenance of Siemens Masterdrives

43 Simovert Masterdrive drives from 0.75 kW to 700 kW

To safeguard the reliability of 32 Siemens (6SE70) Masterdrives on a paper machine section

MELEGHY: Preventive maintenance of 24 Siemens Powerblocks drives

Preventive maintenance contract

Emergency repair on a 120KW ABB ACS800 drive

2 LEROY SOMER 600 kW variators

Overhaul of 12 Siemens Torque Simotics T-1FW3 motors

Preventive maintenance for 17 Siemens servomotors and drives

Troubleshooting of an induced draught fan

19 50 kg (2.2 kW) to 5 ton (7.2MW) motor/reducer/ventilator assemblies

Overhaul of an extruder reducer with 2 indexed output shafts

Maintenance électronique et électromécanique de 3 installations Banbury (moteurs CC et variateurs)

Moteur Siemens 450 KW avec mode de refroidissement à eau

Révision d’un moteur CC 540 KW de laminoir

LENGLET IMPRIMEURS : 1€ to reduce your energy bill

Modelling of the HTA/BT electric network

Fiabilisation d’une ligne de décapage

EMC analysis

Modélisation réseau

Reducer polymerizer vibration monitoring

Maintenance method improvement project

Contrat de mesures vibratoires

Contrat de suivi vibratoire

Contrôle par onde de choc de 46 moteurs asynchrones de 7,5KW (400V) à 750KW (5000V)

Remplacement de 4 CN obsolètes 810T par 1 CN Sinumerik 840D sl Siemens

Modification îlot ZF

Remplacement robot presse

Cellule robotisée de dépose résine et convoyage d’une ligne d’emballage de batteries DAIMLER

Robot de palettisation ligne peinture

Robot de lavage de bacs à endives

Digital Twin d’une nouvelle ligne de production

LENGLET IMPRIMEURS : Retrofit variateurs moteurs unités de récupération de solvant

Rétrofit de l’électronique de puissance et de commande d’une ligne de découpe

Rétrofit électrique pont HFX 16T

Motorisation of compressors in a colliery gas compression station

Obsolescence of the oven’s 7 CC ALSTHOM drives

Retrofitting of an impressive balancing bench

Retrofit of a machine for superfinishing machined parts

Retrofitting of the robotics part of a nine-colour printing line