Preventive maintenance contract

Annual contract since 2012 / 800 hours per annum

4 technicians

Client expectation

In order to compensate for the obsolescence of their pool of more than 300 variators and the increasing number of breakdowns, a semi-conductor (electronic chip) manufacturer wished to set up a strategy in order to better use its variators between now and 2030.

DV GROUP Solution

After several corrective operations, we suggested our client set up maintenance strategies according to the power of the variators, their disrepair and criticality in the process.

At first, we decided to use preventive solutions together with retrofitting in order to build up a stock of spare parts and to maintain a high level of MTBF (mean time between failures). Then, in order to reduce the MTTR (mean time to repair), we undertook to intervene within 24 hours.

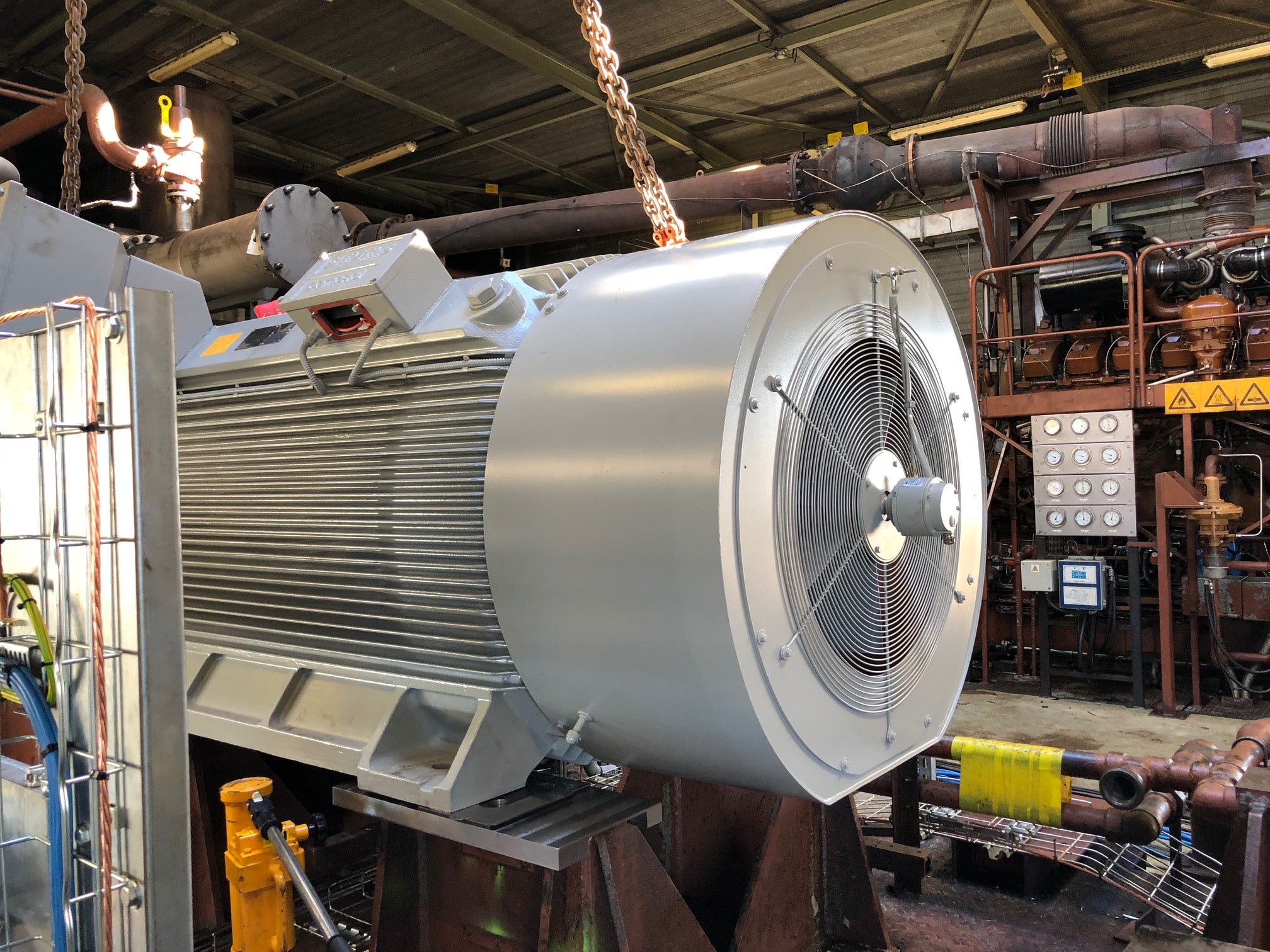

Consequently, the complex AFE-type or low harmonic variators undergo preventive maintenance every 7 years, the intermediate power variators (15-45 KW) controlled via profibus DP undergo preventive maintenance every 10 years and solutions for the replacement of smaller variators (lower than 15 KW) are planned.

Work carried out

The work carried out revolves around 5 elements:

- Preventive maintenance:

Reliability of the variators through the replacement of all ageing components (replacement of electrochemical capacitors, relays and ventilators, change of the continuous bus, reconditioning of the turbine with the replacement of the start-up condenser, monitoring of the IGBT modules with the replacement of the thermal paste, upgrading of the AFE filter) through their purging (improved variator cooling).

- Functional analyses:

Full studies of the parameters of the different variators in order to supply our client with a written analysis explaining their operation and thus minimising stoppage time in the case of troubleshooting or retrofitting.

- Retrofitting:

Replacement of targeted variators in order to modernise the client’s pool and the storing of the obsolete product (the retrofitted variators are reconditioned by DV GROUP and put back into stock by the client).

- Economic management of the small variators <15 KW

Onsite recovery of the variator programs and diagrams in order for them to be archived in a database.

- Onsite troubleshooting

Diagnostic operations and onsite troubleshooting following machine stoppages. Work carried out on SIEMENS, ABB, SCHNEIDER and DANFOSS variators.

Gains et bénéfices client

- Parc variateur fiabilisé : Diminution du taux de panne (moyenne de 2 actions curatives par an au lieu d’1 par mois)

- Maitrise des opérations de maintenance : planification et organisation

- Gain économique : cout faible par rapport à une solution neuve (maintenance variateurs AFE : 10K€ ; retrofit : 55 k€)

- Mise à disposition d’un stock de pièces de rechange

- Instauration d’un climat de confiance : échanges fréquents, pérennes et accompagnement d’un interlocuteur dédié DV GROUP