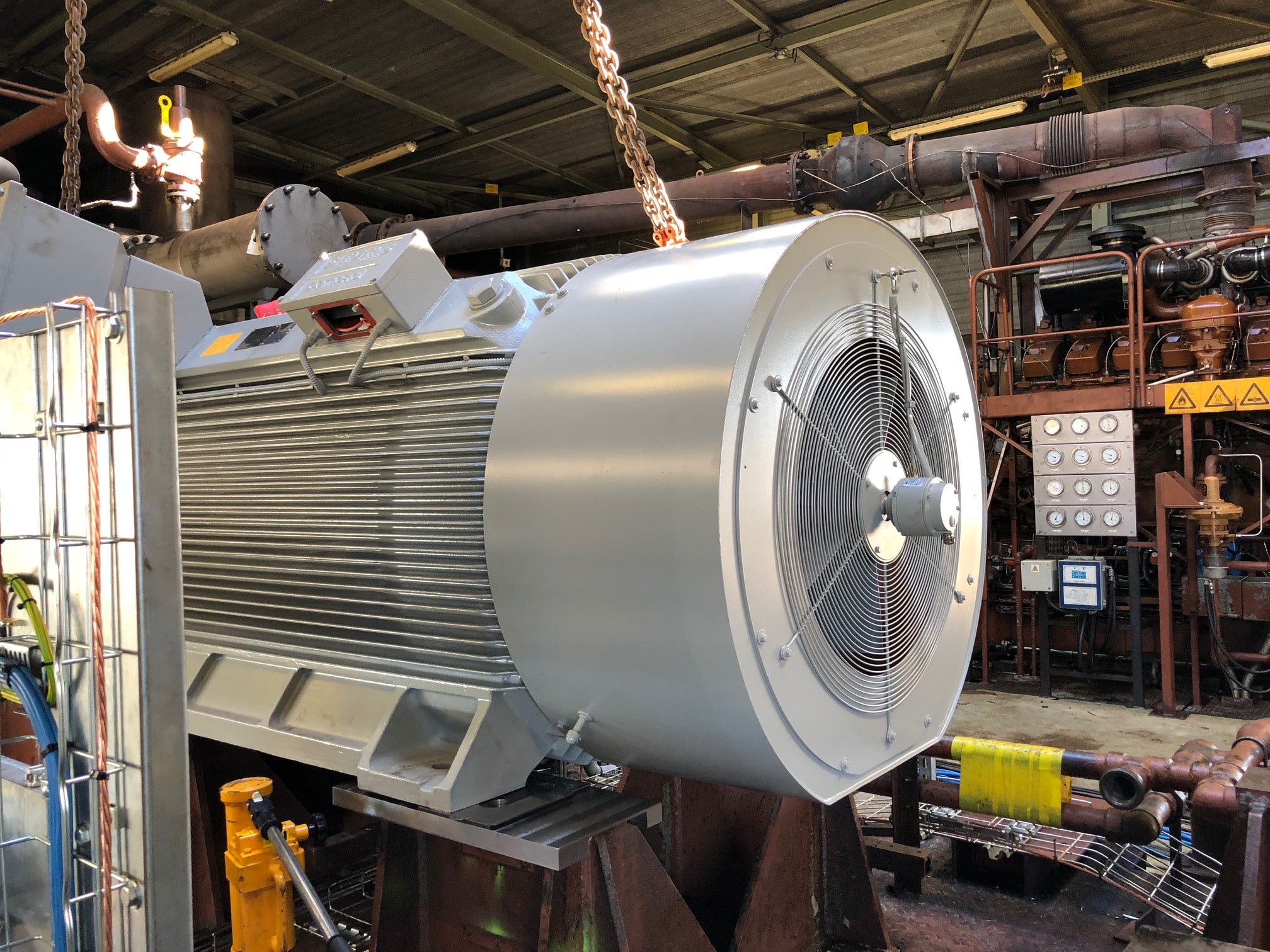

Emergency repair on a 120KW ABB ACS800 drive

Number of project hours: 18 hours

2 technicians

Client expectation

Our client, a leader in the manufacturing of polyethylene films, called us following two breakdowns encountered on two 120 KVA ABB ACS800 drives. Indeed, when the first one broke down at 8.00 pm, our client had immediately installed the drive they had in stock, but at 10.00 pm, that also broke down.

DV GROUP Solution

Our Technical Assistance team immediately sent an expert on site. The diagnosis revealed the failure of an IGBT module characterised by a short circuit between an output phase and the DC bus. The breakdown was identical on both drives. In order to allow our client to restart as quickly as possible, we dismantled the drive on site and brought both defective products back to the workshop in order to carry out an emergency repair.

Work carried out

- Full disassembly of the drive

- Replacement of the IGBT module from DV GROUP stock

- Repair of the IGD card

- Preventive maintenance of the product (upgrading of the electronic cards, replacement of the turbine bearings, cleaning)

- Load test

Our experts worked all night in order to refurbish one of the drives, so our client was able to restart his production line at 8.00 am that morning.

The drive taken from stock was also repaired over the next two days.

Clients gains and benefits

- Speed: emergency diagnosis and repair in order to be able to restart within a few hours

- Savings: low cost compared to replacing with new

- Expertise: efficiency of our Technical Assistance team and intervention by a DV GROUP electronics expert in the middle of the night

Expertise

We provide you with engineering, maintenance and control solutions based on our knowledge of your processes.

Case studies

You may also be interested in

Remplacement robot presse

Cellule robotisée de dépose résine et convoyage d’une ligne d’emballage de batteries DAIMLER

Robot de palettisation ligne peinture

Reduce and understand your energy consumption with SMART ENERGY

Vibration monitoring of a coffee production line

Obsolescence Management: Audit of a Truck Engine Factory’s Equipment Fleet

Repair and reliability of drives

ELOPAK: Corrective preventive electronic maintenance

Preventive maintenance of Siemens Masterdrives

43 Simovert Masterdrive drives from 0.75 kW to 700 kW

To safeguard the reliability of 32 Siemens (6SE70) Masterdrives on a paper machine section

MELEGHY: Preventive maintenance of 24 Siemens Powerblocks drives

Preventive maintenance contract

2 LEROY SOMER 600 kW variators

Overhaul of 12 Siemens Torque Simotics T-1FW3 motors

Preventive maintenance for 17 Siemens servomotors and drives

X-FAB : Replacement of two extractor fans

Troubleshooting of an induced draught fan

19 50 kg (2.2 kW) to 5 ton (7.2MW) motor/reducer/ventilator assemblies

Overhaul of an extruder reducer with 2 indexed output shafts

Maintenance électronique et électromécanique de 3 installations Banbury (moteurs CC et variateurs)

Moteur Siemens 450 KW avec mode de refroidissement à eau

Révision d’un moteur CC 540 KW de laminoir

LENGLET IMPRIMEURS : 1€ to reduce your energy bill

Modelling of the HTA/BT electric network

Fiabilisation d’une ligne de décapage

EMC analysis

Modélisation réseau

Reducer polymerizer vibration monitoring

Maintenance method improvement project

Contrat de mesures vibratoires

Contrat de suivi vibratoire

Contrôle par onde de choc de 46 moteurs asynchrones de 7,5KW (400V) à 750KW (5000V)

Remplacement de 4 CN obsolètes 810T par 1 CN Sinumerik 840D sl Siemens

Robot de lavage de bacs à endives

Digital Twin d’une nouvelle ligne de production

LENGLET IMPRIMEURS : Retrofit variateurs moteurs unités de récupération de solvant

Rétrofit de l’électronique de puissance et de commande d’une ligne de découpe

Rétrofit électrique pont HFX 16T

Motorisation of compressors in a colliery gas compression station

Obsolescence of the oven’s 7 CC ALSTHOM drives

Retrofitting of an impressive balancing bench

Retrofit of a machine for superfinishing machined parts

Retrofitting of the robotics part of a nine-colour printing line