Retrofitting of the robotics part of a nine-colour printing line

Number of project hours: 1,270 hours

Project duration: 52 weeks

10 technicians

Client expectation

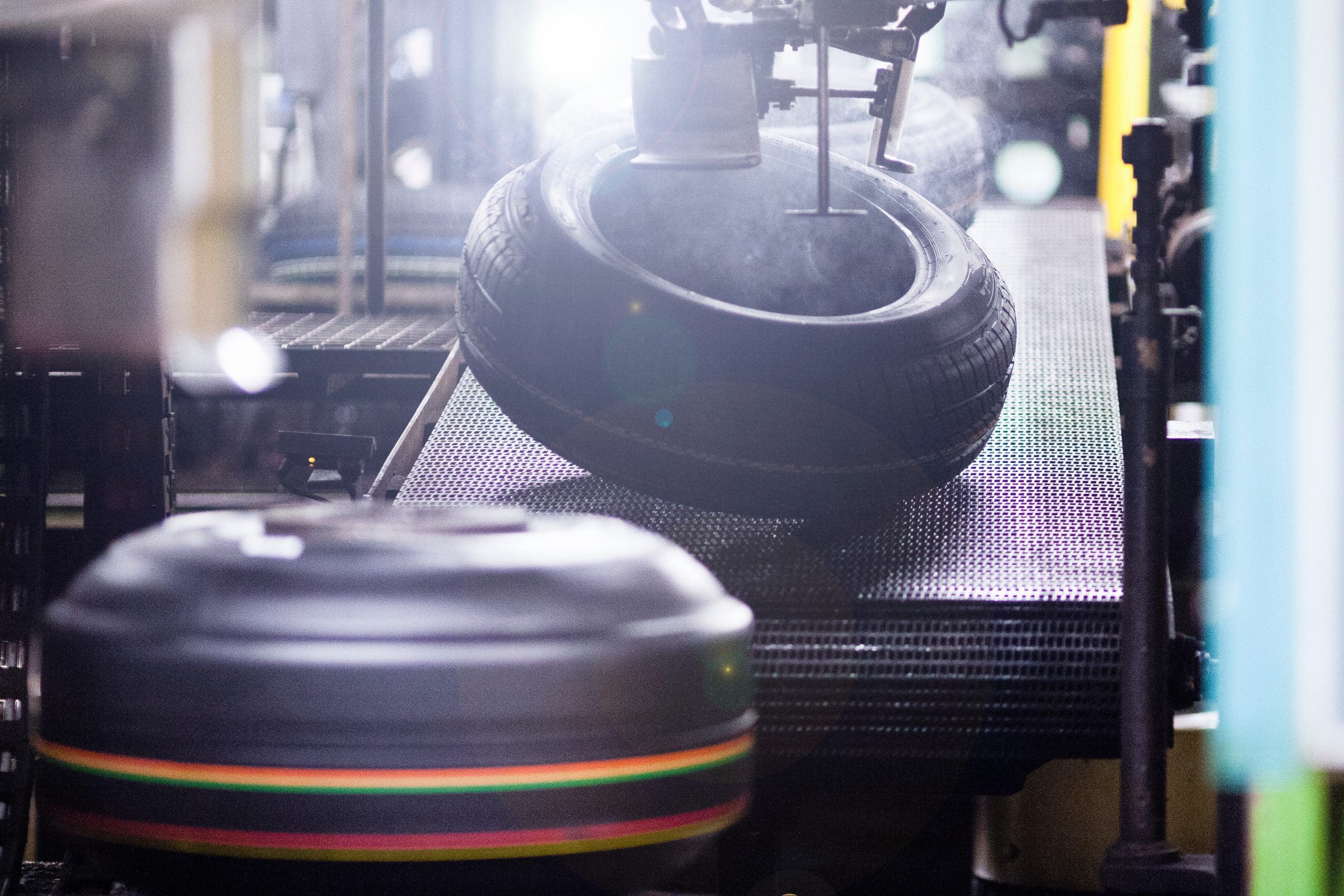

A manufacturer specialising in plastic food wrapping chose to invest in a retrofitting of their nine-colour rotational printing line. The overall obsolescence of the robotics part led our client to re-think the machine system, replacing it with new equipment.

The aims were clear:

- Compensate for the obsolescence of the machine equipment

- Facilitate maintenance on the robotics.

DV GROUP solution

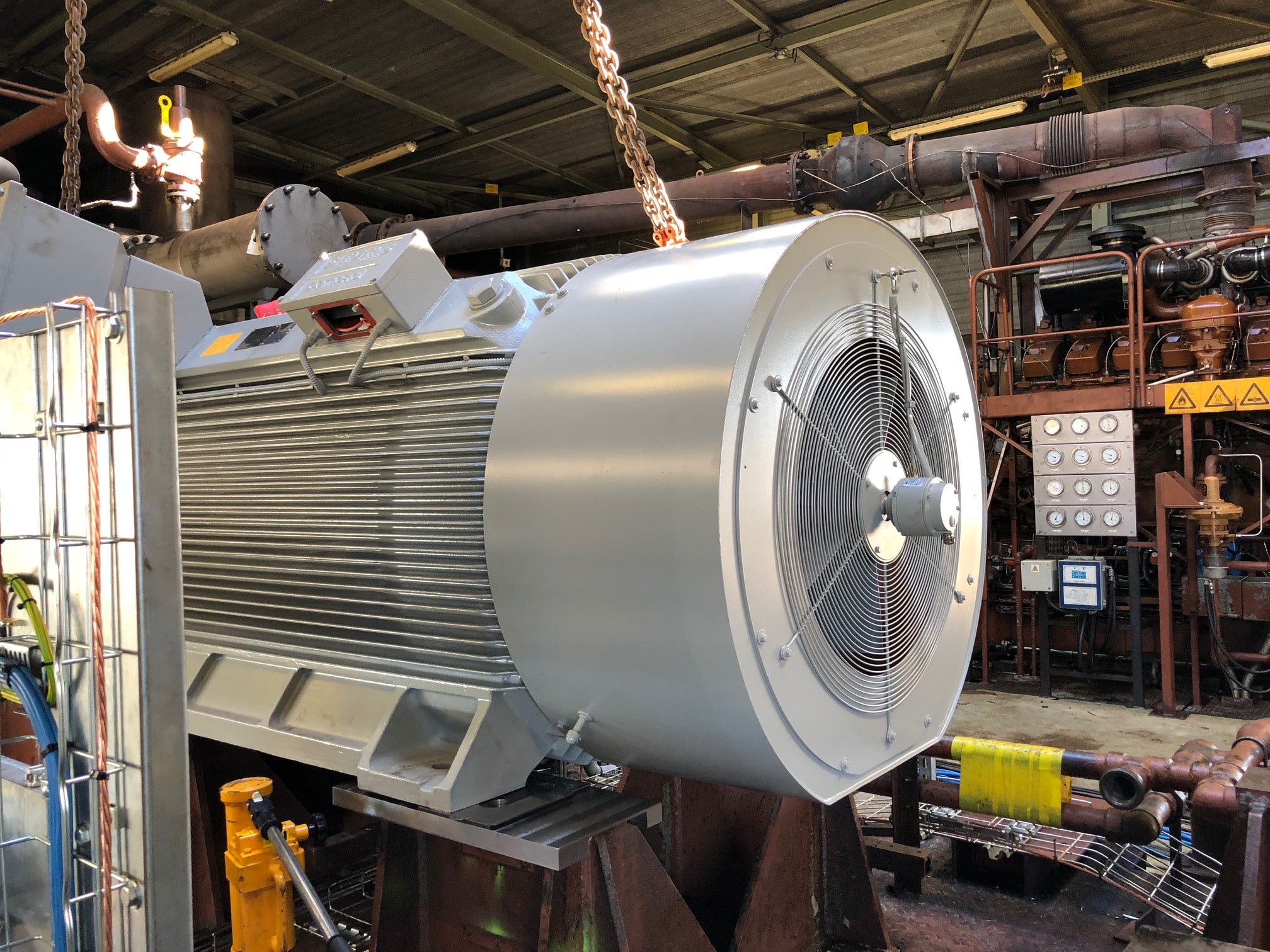

In order to reach these objectives, we proposed our client should replace all the robots on the line in the Siemens S5 range by the S7-1500 range. This replacement also included the transfer of API programmes and the machine network communication protocol, as well as the replacement of the IHM supervisor and the IHMs on the colour groups. Consequently, the experts in our design office were busy for several weeks in order to carry out this retrofitting project and comply with the programmed immobilisation time for this machine, in other words, two weeks.

DV GROUP retrofitted all the Siemens S5 series PLCs on the line with the S7-1500 series.

DV GROUP retrofitted all the Siemens S5 series PLCs on the line with the S7-1500 series.

Word carried out

DV GROUP technical solution:

- Verification of the current equipment configuration in order to define the new one.

- Full back-up of the machine

- Study of communication exchanges between robots

- Preparation work for the implementation of a communications gateway between the new and old equipment

- Approval of the platform

- Switch-over of the APIs onto the machine in several phases in order to diminish stoppage time

- Conversion work on the robot and display unit programmes, drawing of electrical diagrams, supply of equipment.

Following observation of a communication problem, we decided with our client to retrofit the entire machine in one single 15-day stoppage in order to carry out the work (instead of dealing with one printing group per month over 2 stoppage days).

- Full approval with acceptance of the communications platform

- Carrying-out of the work

- Commissioning

- Production assistance.

In the end, the 10 experts in our design office finished the site and commissioning in 12 days, in other words, three days fewer than had initially been scheduled.

Clients gains and benefits

- Perpetuation of the nine-colour rotational printing line

- Facilitated maintenance: machine renewed with standard Siemens products

- Simplified production follow-up thanks to data feeds

- Operators’ support.