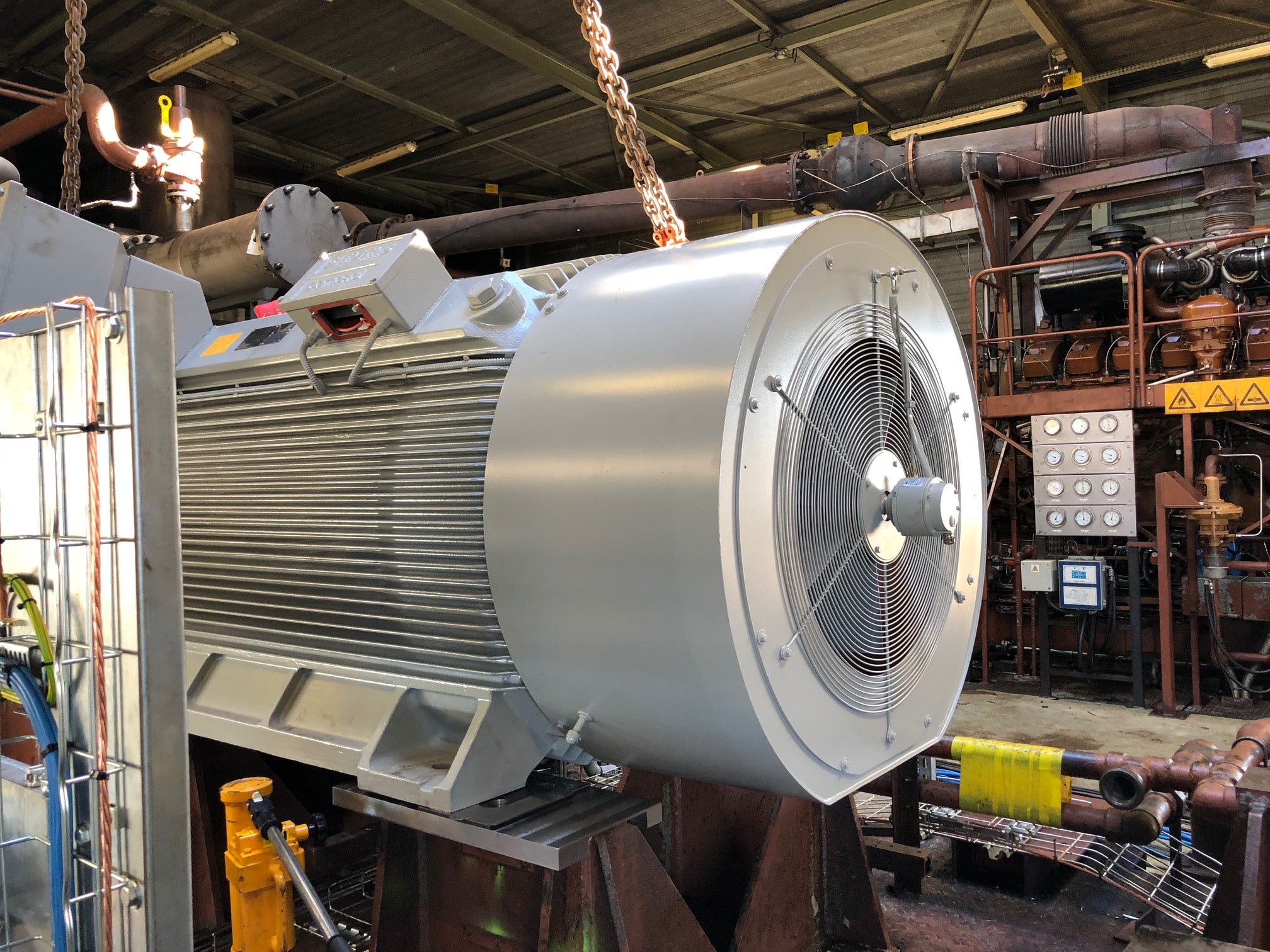

19 50 kg (2.2 kW) to 5 ton (7.2MW) motor/reducer/ventilator assemblies

Number of project hours: 290 hours

4 technicians

Client expectation

Each year, out client, a ready-to-use cement, aggregates and concrete manufacturer, undertakes technical stoppages in order to maintain its ovens. Indeed, the cement manufacturer takes advantage of these 3-week stoppages to replace a large number of machines and thus overhaul the dismantled equipment. In order to be totally trouble-free with their running and restarting, he wished to work with a reliable partner who would:

- take responsibility for the overall operation

- know how to manage the electrical and mechanical parts of the drive system

- provide a technical guarantee for operations allowing secure restarting

- comply with the safety regulations

DV GROUP Solution

Satisfied with our expertise and our offer, our client chose to grant us the exclusivity of the replacement / overhauling of machines during its technical stoppages. This time, for our fourth collaboration, the experts from our electro-mechanical agency in Saint-Priest were mobilised for 3 weeks to process 19 machines (moto-reducers, moto-ventilators and motors) from 50 kg (2.2 kW) to 5 tons (7.2MW) and to keep to the deadline set by our client.

Work carried out

DV GROUP technical solution:

Disassembly/reassembly of 19 motor/reducer/ventilator assemblies

- Site management

- Implementation of safety regulations

- Implementation of appropriate lifting means and transport

- Electric cable dismantling / mechanical disassembly and reassembly

- Swapping of couplings and hydraulic couplings

- Laser alignment of direct drives and pully/belt systems

- Machine trials

- Site cleaning

Overhauling of 5 moto-ventilators and moto-reducers in the workshop

- Monitoring of the electrical part (insulation, resistances, shock wave, index)

- Monitoring of the mechanical part (bearing seats, joints, interlocking)

- External and internal depollution via cleaning and steaming

- Dynamic balancing of the turbines

- Monitoring of reducers: lubrification, waterproofing, gearing

- Changing of the bearings and SKF range joints

- Anti-flash finish

- Empty and loaded testing on the trial platform

Gains et bénéfices client

- Global offer from DV GROUP: total management, from site preparation to a technical validation report and feedback on the experience at the end of the stoppage

- Control of procedures and of the environment

- Compliance with the budget and deadlines

- Technical security

- Establishment of a climate of trust: frequent, on-going exchanges and support from a dedicated DV GROUP contact