Reducer polymerizer vibration monitoring

Number of project hours: 30 hours

Project duration: Rental since December 2021

Client expectations

The Predictive Control department has signed a three-year contract for the vibration monitoring of the Polybatch sector’s machinery (up to 4 checks per year). This equipment is essential for production, and the entire unit could be brought to a standstill in the event of failure. What’s more, our customer’s production mode requires 24/7 operation, with only one maintenance shutdown every two years. It is therefore impossible for him to schedule a specific shutdown to change the polymerizer reducer. He would therefore like to install a continuous measurement solution on this reducer, so as to be warned if degradation accelerates.

DV GROUP solution

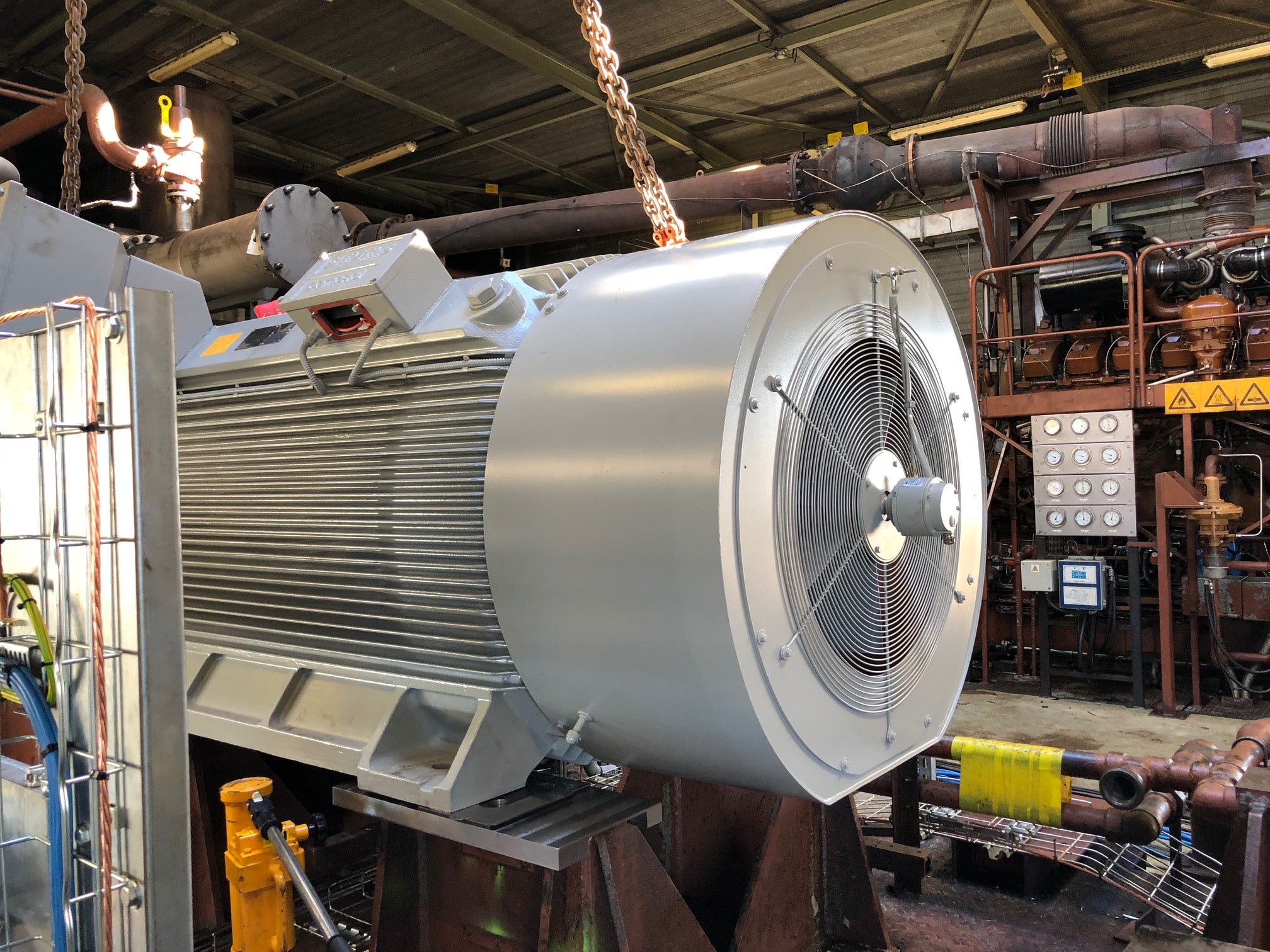

We suggested to our customer that he should install a sensor-based monitoring system. This will enable us to monitor the equipment continuously, and to warn our customer well in advance if the deterioration of the gearbox becomes too serious. It will also enable him to organize an extraordinary shutdown to replace the gearbox, and avoid a breakdown that would render the entire batch unusable during production.

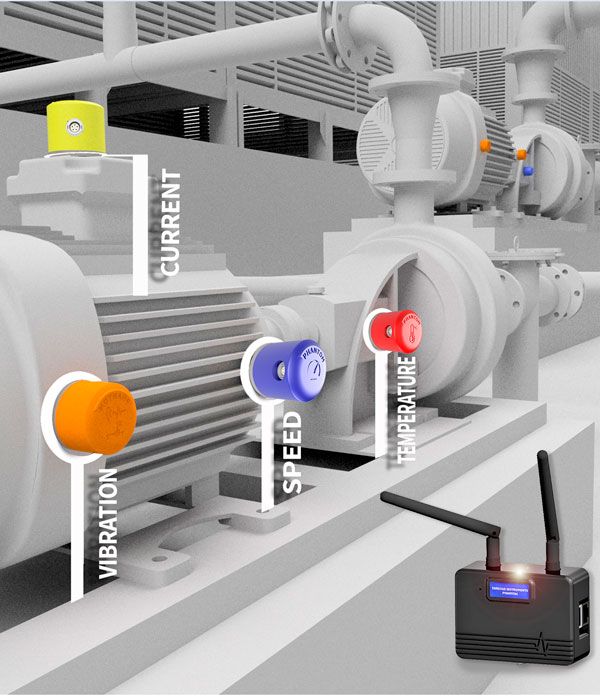

Technical Zoom: Equipment used

4 triaxial vibration transducers, a remote acquisition unit outside the building due to ATEX zone

Machine monitoring

Work carried out

- Installation of sensors on the gearbox

- Installation of measurement box

- Creation of customer database

- Set alert and alarm thresholds (received by e-mail)

- Weekly data analysis and expert report sent to customer

- Organization of monthly meetings to review the previous month’s measurements, and consider maintenance action or monitoring extension.

Client benefits

- Peace of mind for our customer: his gearbox is under constant surveillance

- Precise reports on the evolution of gearbox degradation

- Technical exchanges and advice on gearbox maintenance

- Anticipated organization in the event of an extraordinary production shutdown