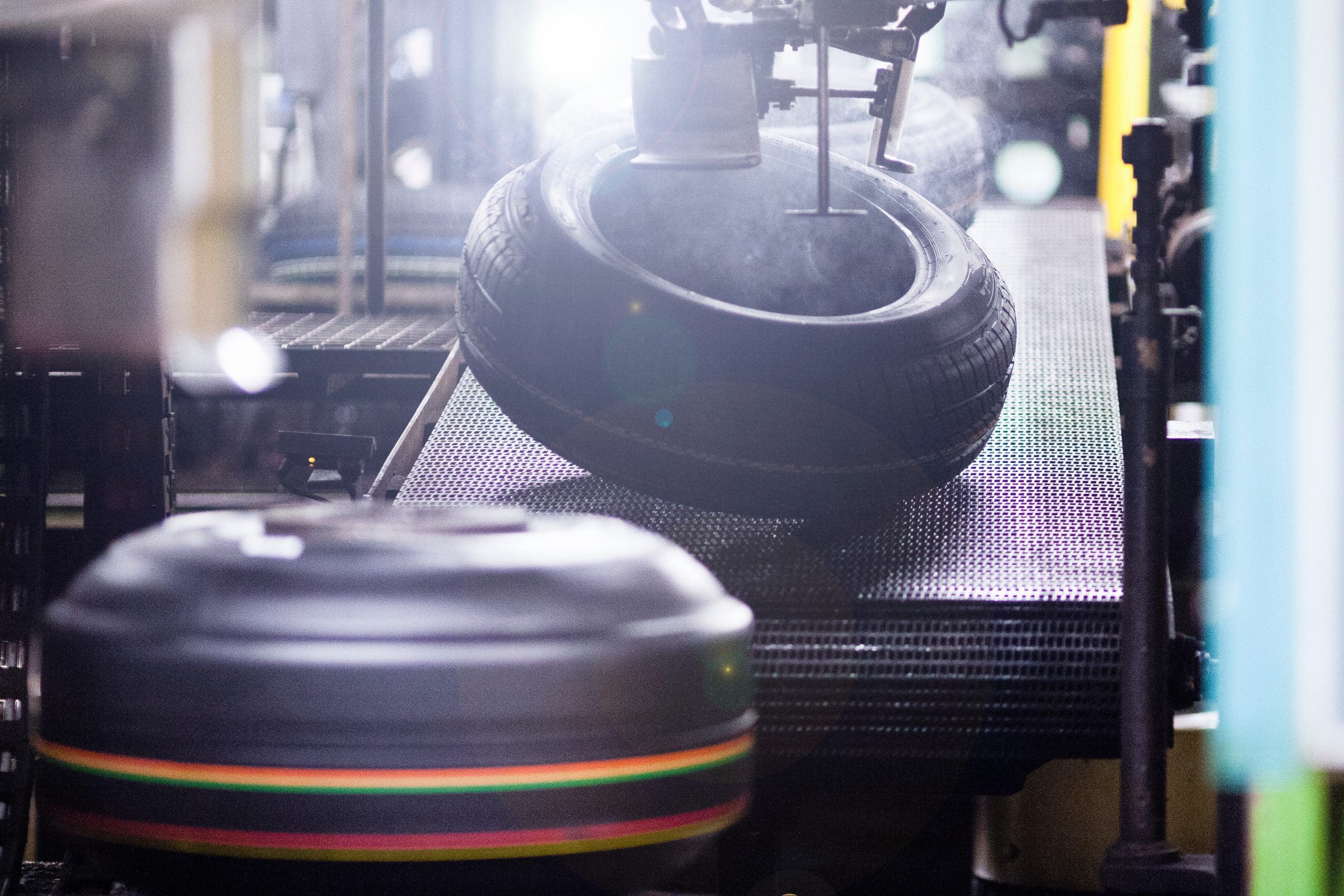

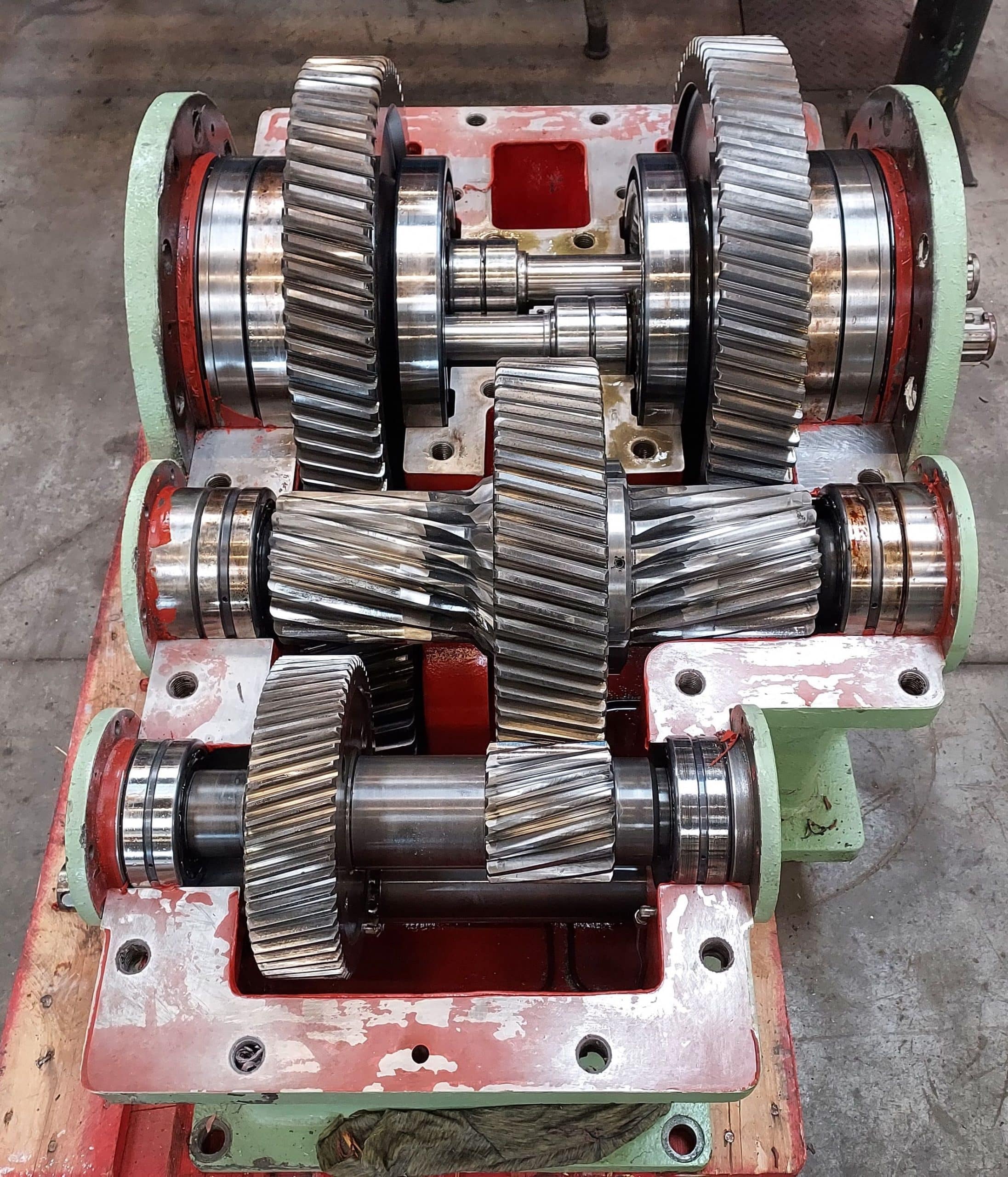

Overhaul of an extruder reducer with 2 indexed output shafts

Number of project hours: 200 hours

3 technicians

Client expectation

Given the importance of the co-extruder in their manufacturing process, a French plasticisation company wished to entrust to us the overhaul of the only reducer they had in stock in order to guard against a possible mechanical breakdown.

DV GROUP Solution

In fact, a breakdown of the co-extruder would systematically lead to the stoppage of half of production and as the lead time for the supply of a new reducer would be extremely long, out client could not afford not to have a product in stock. In order to be totally worry-free regarding the condition of the only reducer they had in stock, it was imperative to overhaul it.

Work carried out

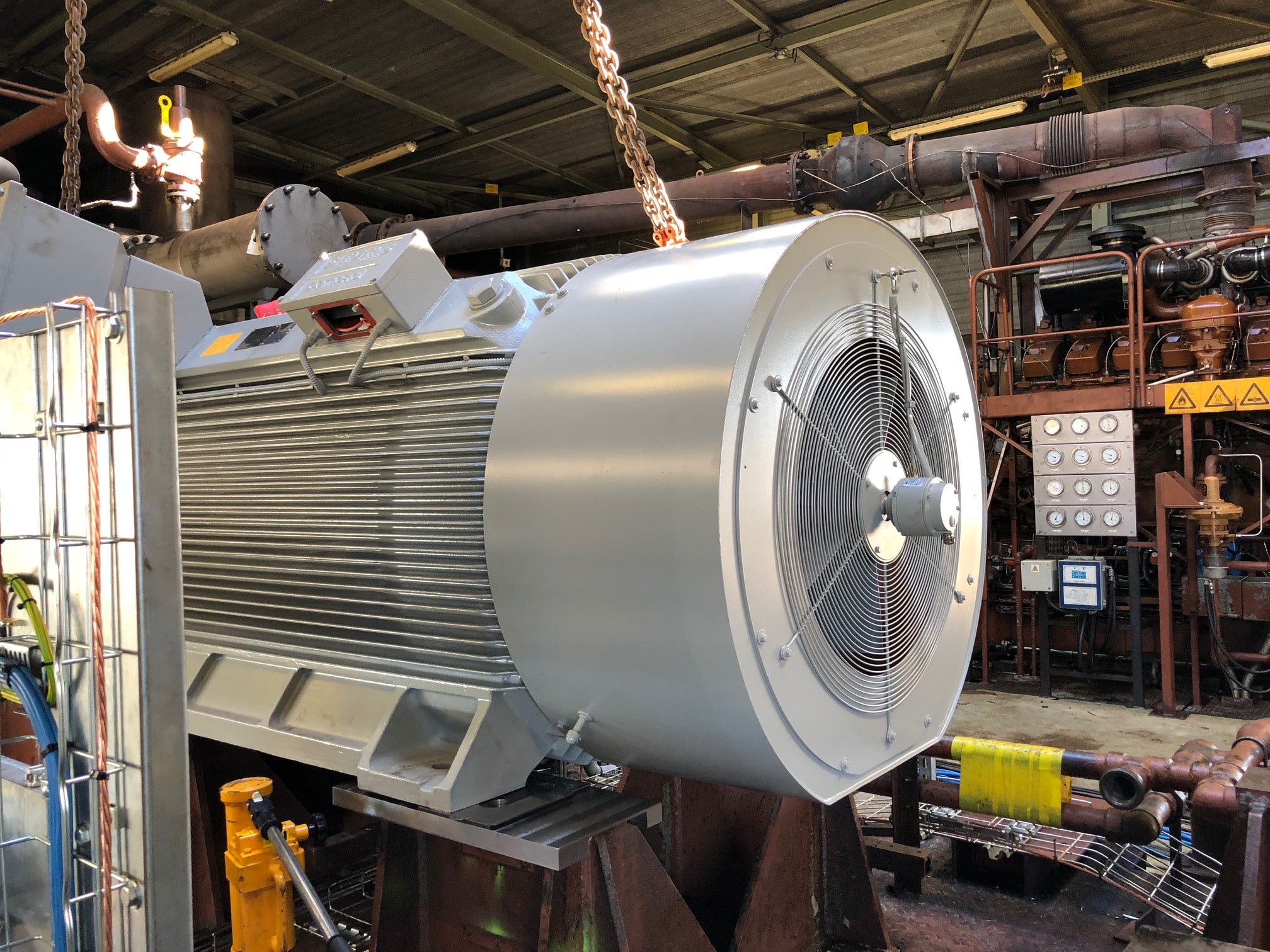

DV GROUP technical solution:

3D printing of the shafts’ clamping matrix:

- Given the particularity of an extruder reducer with 2 indexed output shafts, we suggested to our client modelling and 3D-printing the shafts’ clamping matrix in order to guarantee their correct positioning during refitting.

Removal/refitting and overhauling of the reducer in the workshop:

- Visual monitoring of the product

- Measurement of the axial play in the gearing rows

- Benchmarking of the bearing references

- Visual appraisal of tooth spacing (search for the usual signs of deterioration of the teeth)

- Monitoring of the span of the teeth with an impression of the teeth on scotch tape

- Removal of the gearing rows

- Monitoring of the size and geometry of the shaft rows

- Magnetic particle inspection of the teeth

- Inspection of the key grooves and connector spokes by bleeding

- Inspection of the casing size

- Cleaning of the reducer and gearing rows

- Reassembly of all the bearings and joints

- Monitoring and adjustment of the span of the teeth and indexation

- Adjustment of the axial play in the gearing rows

- Reassembly of the cover, waterproofing and upper casing

Clients gains and benefits

- Savings: low cost compared with a new solution

- Stock: availability of a refurbished reducer in stock

- Speed: shorter lead time compared with a new solution

- Trust: establishment of a climate of trust (frequent, on-going exchanges and support from a dedicated DV GROUP contact)