ELOPAK: Corrective preventive electronic maintenance

Context

Our client, a packaging manufacturer in the southwest of the Netherlands, is experiencing an increase in breakdowns on their machines equipped with Lenze servo-drives.

Problem

After investigation, we find that these drives are obsolete.

DV GROUP solution

We proposed to our client a corrective preventive workshop of all his drives.

In agreement with him, we proceeded by rotating 20 drives.

Arrival of the 20 modules in our workshops: Overhaul in less than 3 weeks : Delivery to the client

The client then exchanges his overhauled and corrected drives with those installed in his machines, then sends us a new batch… Until the complete overhaul of his 120 drives!

The advantages ?

No production downtime for our customer thanks to the rolling method

Reliability of the machines and the stock is achieved quickly: within 6 months.

Economically interesting solution compared to retrofitting.

Expertise

Wij bieden u engineering, maintenance, en control oplossingen op basis van onze kennis van uw processen.

Praktijkvoorbeelden

Mogelijk bent u ook geïnteresseerd in

Repair and reliability of drives

Preventive maintenance of Siemens Masterdrives

43 Simovert Masterdrive drives from 0.75 kW to 700 kW

To safeguard the reliability of 32 Siemens (6SE70) Masterdrives on a paper machine section

MELEGHY: Preventive maintenance of 24 Siemens Powerblocks drives

Preventive maintenance contract

Emergency repair on a 120KW ABB ACS800 drive

2 LEROY SOMER 600 kW variators

Overhaul of 12 Siemens Torque Simotics T-1FW3 motors

Preventive maintenance for 17 Siemens servomotors and drives

X-FAB : Replacement of two extractor fans

Troubleshooting of an induced draught fan

19 50 kg (2.2 kW) to 5 ton (7.2MW) motor/reducer/ventilator assemblies

Overhaul of an extruder reducer with 2 indexed output shafts

LENGLET IMPRIMEURS : 1€ to reduce your energy bill

Modelling of the HTA/BT electric network

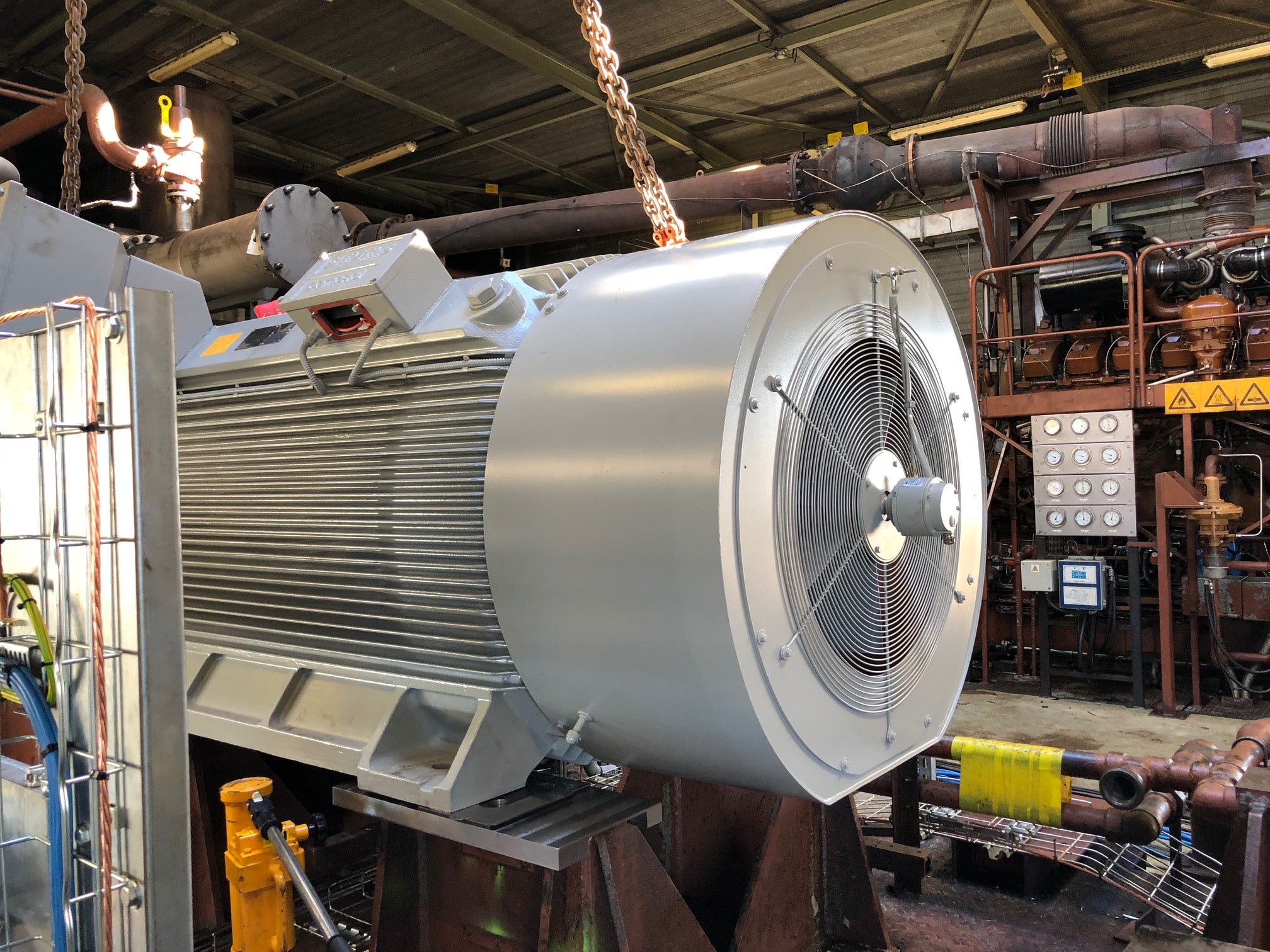

Motorisation of compressors in a colliery gas compression station

Obsolescence of the oven’s 7 CC ALSTHOM drives

Retrofitting of an impressive balancing bench

Retrofit of a machine for superfinishing machined parts

Retrofitting of the robotics part of a nine-colour printing line