LENGLET IMPRIMEURS : 1€ to reduce your energy bill

Number of project hours: 568 hours

Project duration: 6 months

Client expectation

Our client wished find the best way to manage and monitor its energy consumption. It needed a solution which would allow it to:

– Improve the energy piloting of its production equipment

– Reduce its energy consumption

– Better understand the consumption of its various production equipment to prioritise its investments in order to improve the energy efficiency of its industrial site.

DV GROUP solutions

In order to face its problems in relation to energy, we suggested a turnkey solution for monitoring its gas and electricity consumption:

We integrated our vertical Smart Energy, with 24-hr connected technical assistance, to the operation of the solution.

Thanks to EEC grants, the project only cost our client 1 euro(*).

Our Smart Energy solution includes:

– The implementation of energy monitoring software

– Training and technical assistance for the client

– The definition and implementation of energy efficiency solutions on its principal equipment (rotary printing presses), based on our client’s “energy map”.

– The financing of the project thanks to the CEE IND UT 134 facility.

Word carried out

DV GROUP technical solution:

– Prior CEE IND UT 134 study

– Measuring system with energy performance indicators

– Studies and electrical works (counting equipment)

– Industrial computer designs (operational specification, configuration, commissioning)

– Training of the client’s staff

– Technical assistance service

Equipment implemented

- Energy counting captors (65 counting points for electricity, gas and compressed air) radio-connected (standard LoRaWAN)

- Interface with the production management software (ERP) to recuperate manufacturing order data (m2 of surface area of printed paper)

- Smart Energy software

The Smart Energy software ensures:

- the acquisition of counting information from the captors and machines

- the processing of flows in real time (calculations and regulations)

- interfaces with the production management software (ERP) and energy suppliers (electricity, gas etc.)

- the availability of the results in the form of graphics and energy performance indicators

- an alert to users regarding abnormal consumption

- an aid for exploiting the energy data.

Vues du logiciel SMART ENERGY

Vues du logiciel SMART ENERGY

Clients gains and benefits

- Expected energy savings: 5 to 10 %

- Real-time and exact knowledge of the various consumptions

- Knowledge of the energy performance indicators (KWh/m2 printed) and energy costs associated with each type of printed paper

- Decrease in stoppages

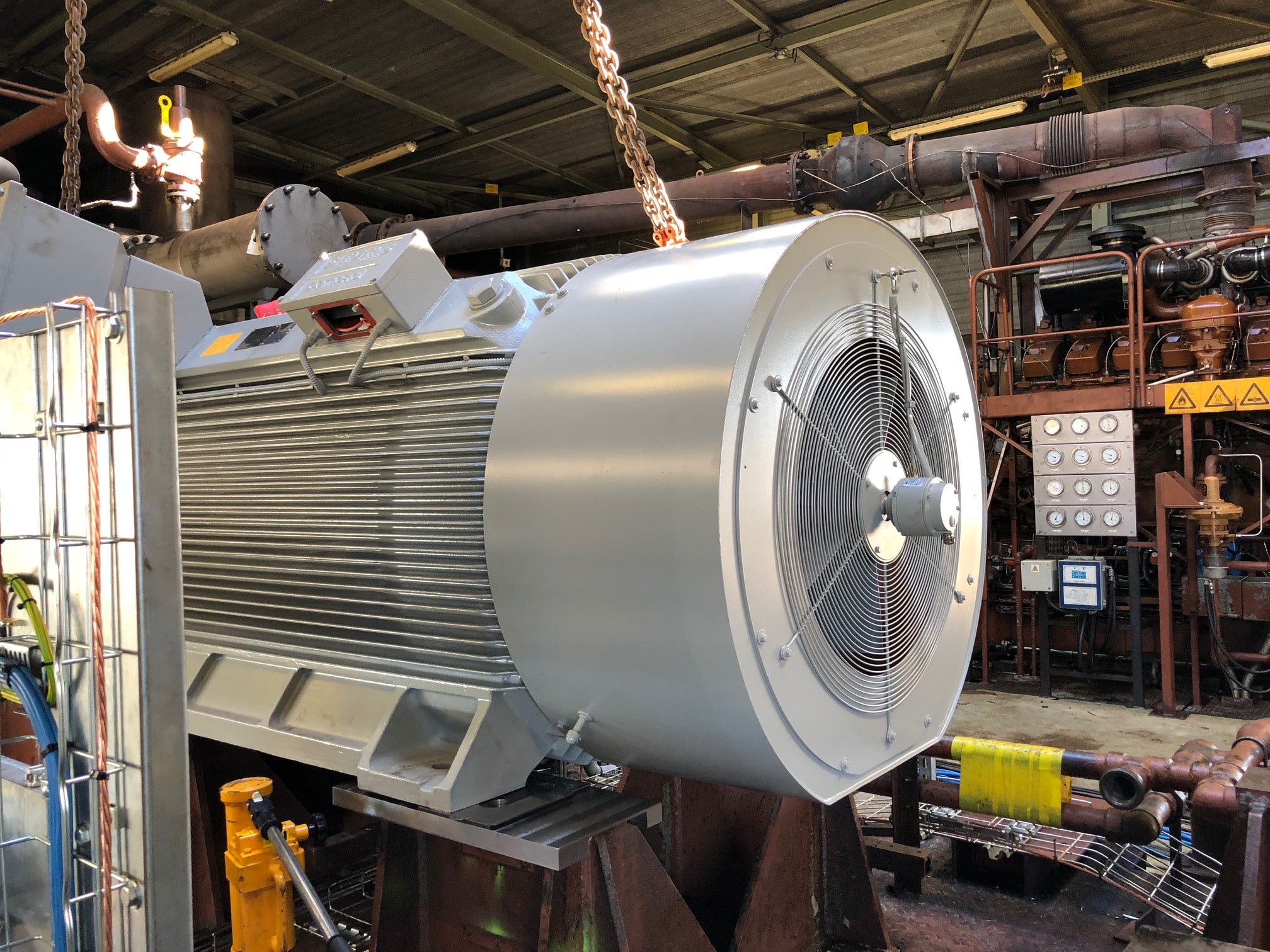

The client has thus been able to prioritise significant investment on drives (motors and speed controllers) of its 4 rotary presses in order to increase even more the energy efficiency of its production installations.