Modification of the ride “Tonnerre 2 Zeus” [Zeus’ Thunder]

Number of project hours: 1,400 hours

Project duration: 6 months

No. of technicians: 6

Client expectation

Within the context of the attraction’s renovation, the Astérix amusement park wanted to invest in a new track, as well as a new train for its most popular ride, Zeus’ Thunder.

The park was therefore looking for an integrator capable of linking the new elements to the existing automatism, while responding to new improvement requirements:

– modernisation of the maintenance track

– improvement in the lift’s grip speed

– modernisation of the braking system

– modernisation of the control voltage

DV GROUP solutions

In order to understand the project correctly and reach the objectives, we proposed a two-phase management:

Phase 1: Pre-design

We carried out onsite surveys of the electrical cabinet installation and the various captors and actuators which would be modified or integrated into the track and on the doubling of the maintenance track. We then modelled the robot program in the design office. Lastly, we organised an onsite visit in partnership with TÜV. These steps allowed us to draft the operational specifications file related to the train modifications (track and doubling of the maintenance track), which we presented to our client.

Phase 2: Implementation of the project following validation

- Replacement of the robot’s CPU, with an increase in memory size in order to increase reactivity.

- Addition of an on/off switch at technical room level in the station and the maintenance track

- Integration of Flip Flop management for the second maintenance track in the technical room

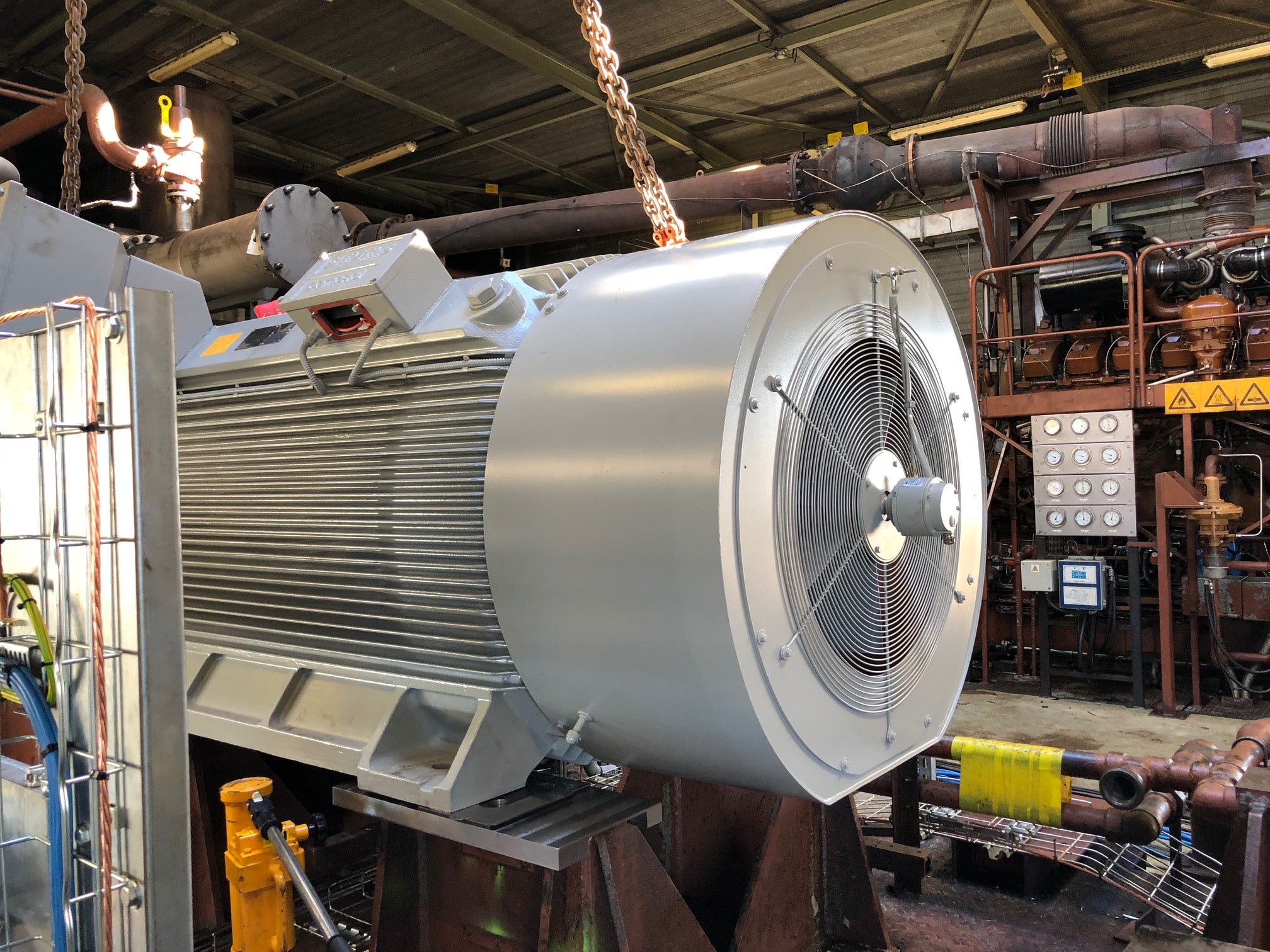

- Replacement of the tyre casings allowing the train to brake before arriving in the station

- Cabling of the various actuators and captors allowing the ride to be driven correctly

- Exchanges with the SYSTEMA security, monitoring and validation bodies

- Replacement of the lift cupboards and station management cabinets

- Modification of the cycle times allowing a faster train grip speed

- Connection of the lift drive

- Addition of an operator detection mat in order to validate presence during the ride operating phases

Equipment implemented

Automation :

Rockwell Control Logic and separate on/off point solution

RFID chip for all trains

Electrics :

Upgrading to European control voltage standards: 110V (American standard) to 24V

Realisation of 5 cupboards comprising all the communication and control exchanges and the motor feedback

- 1 cupboard for the lift

- 1 cupboard for the maintenance room

- 1 cupboard under the station

- 1 pneumatic distribution cupboard

- 1 variable speed cupboard

Drive :

Integration of Schneider brand drive

Pneumatics :

Integration of a Festo pneumatic distributor for the management of the brakes on entry into the station and parking

Work carried out

DV GROUP technical solution:

IN THE WORKSHOP :

Realisation of electrical designs

Realisation of API designs

Realisation of drive designs

Supply and manufacture of cupboards in the workshop

ONSITE :

Integration of the various cupboards

Fitting of cable paths and power and control cables

Connection of the various bodies (gates, brake, harness etc.)

Implementation

“Your experts have made every effort to open the attraction on time. Whether humanly or professionally I am very satisfied with our collaboration”

Maintenance Manager at Parc Asterix

Responsable maintenance au Parc Astérix

Read the interviewClients gains and benefits

- The modification of the lift grab and the number of cycles during the opening phases have been increased, allowing the ride a maximum gain in speed of 0.03m/s, thus leading to an increase in its capacity of welcoming visitors.

- Facilitated maintenance, optimisation of ride cycles and better reporting of the ride’s operation states thanks to:

- the lift’s communication which allows a fault report to show in the control centre

- the integration of the new maintenance cupboard allowing Flip/Flop management

- the integration of variable speed which facilitates maintenance access

- RFID chips on all the wagons allowing a better monitoring of the train management

- DV GROUP and the Parc Astérix have recalculated the train speeds in order to ensure the ride’s correct operation.