To safeguard the reliability of 32 Siemens (6SE70) Masterdrives on a paper machine section

Number of project hours : 28 hrs

Technicians : 2

Client expectation

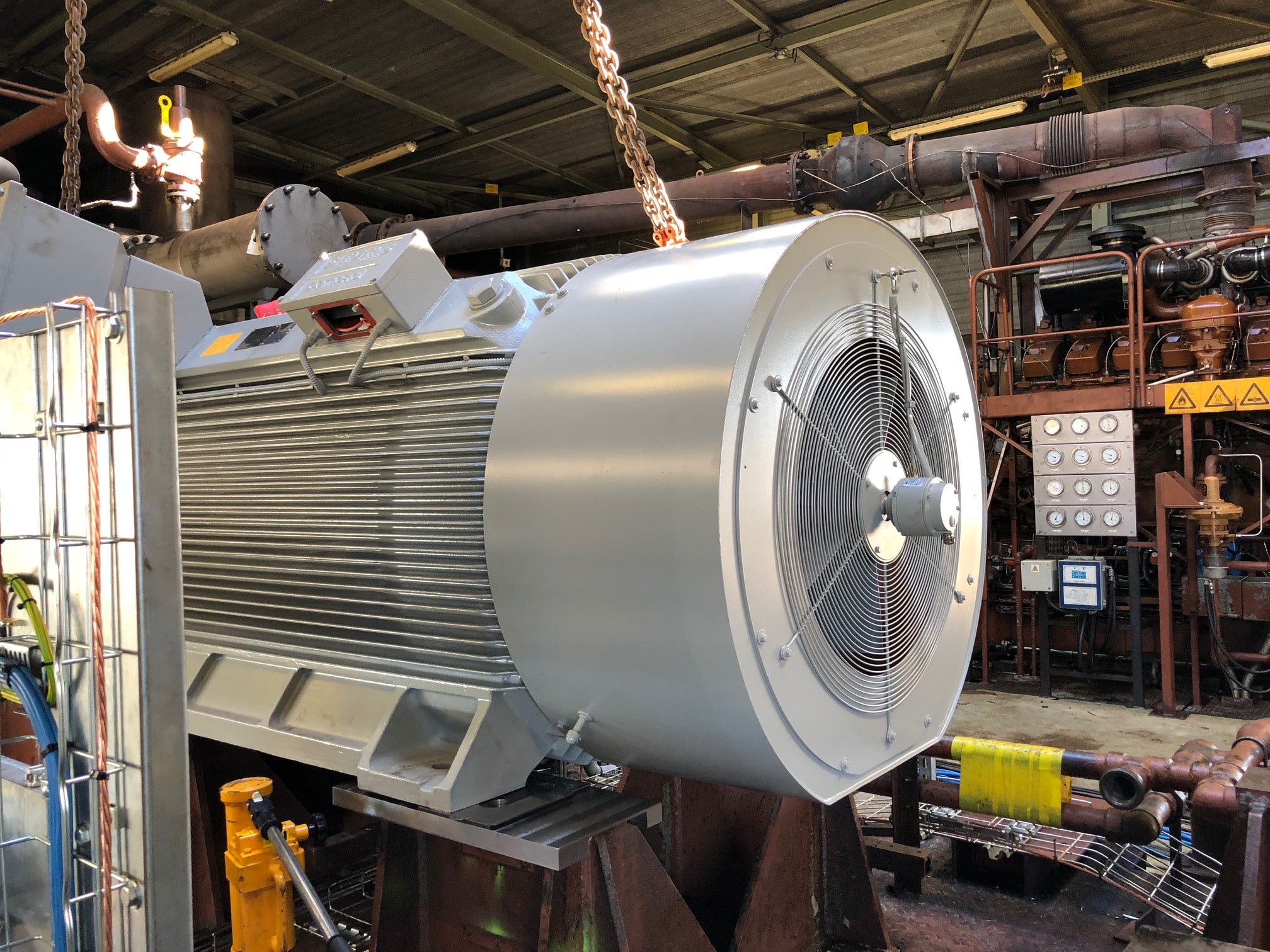

The DV GROUP team travelled to Austria for a paper-manufacturing client specialising in packaging and corrugated cardboard. The company called on our expertise to safeguard the reliability of the VAC Drive and Siemens Masterdrives (55 kW – 400 kW) section during their production shutdown. The technicians faced several constraints:

- The condition of the drives was unknown

- The equipment was obsolete

- There was a significant breakdown rate

- And production is only stopped for only two days a year.

DV GROUP Solution

For this type of intervention, a service including the disassembly of the products is usually carried out, but the geographical distance and factory stoppage time made this solution impossible. In addition, the analysis of the situation did not allow a precise current MTBF (Mean Time Between Failures) of the section to be obtained, so it was difficult to determine the measures necessary to suit the client’s budget and return on maximum investment.

DV GROUP offered a step-by-step solution:

- Diagnosis of the onsite products:

- Definition of the urgent measures to be carried out to significantly increase the MTBF

- Definition of the pertinent preventive measures to obtain maximum ROI within the client’s budget

- Decontamination of the section

- Program safeguarding

- Refurbishing of the cooling circuit, integrating an exchange of the turbines

Word carried out

The DV GROUP team safeguarded the reliability of the section within the allotted two days. Following their analysis, the technicians realised that three variators were presenting faults: the condition of the PCB IVI, IGB and PSU was very impaired. Remedial work was carried out in keeping with the preventive steps.

Clients gains and benefits

-

A recommendation for a second phase adapted to the client’s budget constraints

-

Improved ROI

-

Increase in MTBF

-

Increase in machine availability

-

Alert to new risks to be taken into account

-

Prioritisation of measures to be carried out

-

An operation appropriate to the client’s budget constraints