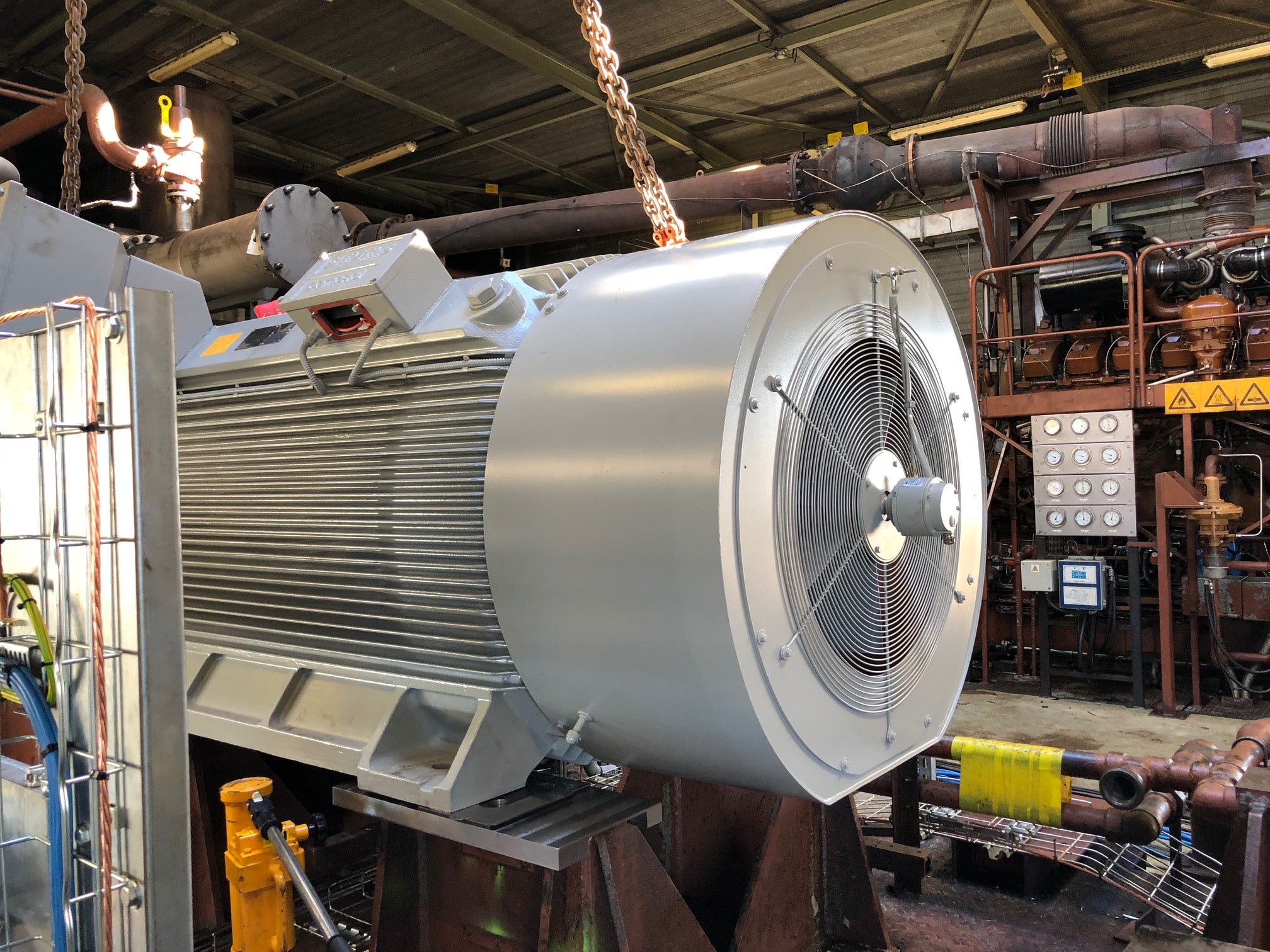

Troubleshooting of an induced draught fan

Number of hours dedicated to the project: 65 hours

Client expectation

Our client is a waste reclamation and processing centre. They contacted us following an outbreak of fire on a bearing of the 450 kW electric cooling fan, causing a site shutdown.

DV GROUP Solution

Emergency intervention by the Electro-mechanical teams that same night.

When our experts arrived onsite, it appeared that the bearing had welded itself to the shaft. The decision was therefore made to displace the bearing housing in order to be able to carry out an emergency repair. Three teams from Cambrai and Grigny were required day and night in order to complete the work.

The client restarted production the next evening.

In order to secure production, we put in place continuous machine feedback.

Work carried out

- Machine monitoring using a Phantom captor for feedback following the work

- Replacement of bearing housings, onsite modification of the chassis in order to displace the housing fixing

Clients gains and benefits

- Restarting of production within a few hours: reduction of stoppage time

- Machine feedback in order to anticipate any faults