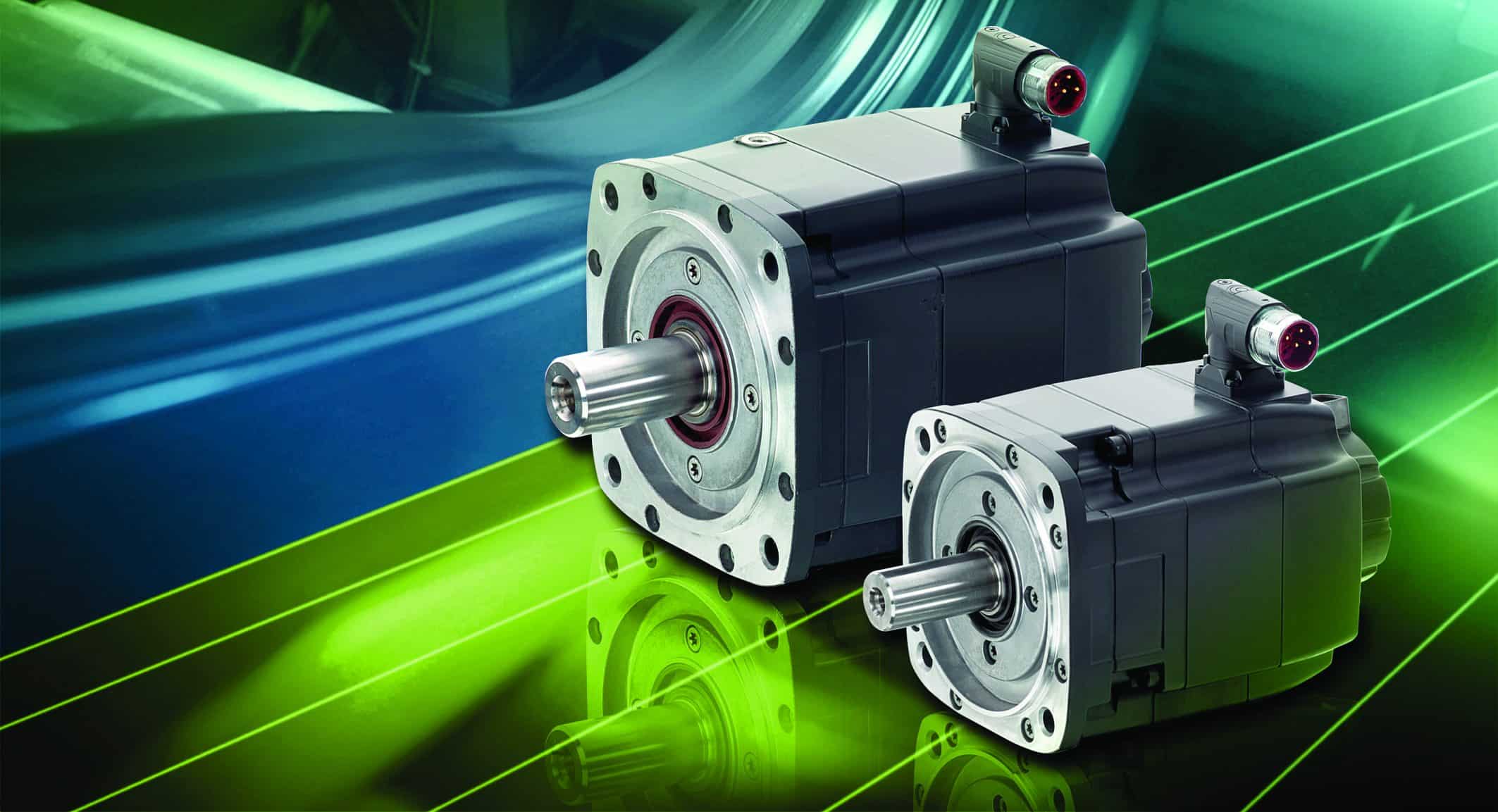

Preventive maintenance for 17 Siemens servomotors and drives

Client expectation

Our client, a metals processing specialist, recently chose to invest in the preventive maintenance of their boring machine stock. Indeed, following several breakdowns of motors and variators owing particularly to the polluted environment and the obsolescence of some of the equipment, our client wished to secure its production tool and thus be trouble-free regarding its availability.

DV GROUP Solution

Satisfied with our expertise and our offer, our client chose to entrust us with the annual maintenance of its boring motors and variators. This time, for our 3rd collaboration, the experts from our electro-mechanical agency in Clarques and our electronics agency in Douvrin were mobilised for 15 days to process 17 motors and 17 variators and to keep to the deadline set by our client.

Work carried out

DV GROUP technical solution:

Full restoration of the servomotors:

- Full mechanical overhaul, including the replacement of joints and bearings.

- Replacement of parts necessary for the restoration to the nominal characteristics of each motor: brakes, encoders, tachygraphs or Hall-effect captors.

- Repair of mechanical elements found to be on the threshold or outside nominal mechanical tolerances: flange racks, seal bearings or bearings loadings.

Preventive maintenance of variators:

- An overall check of the product: rust, pollution, plastics processing, chassis, settings etc.

- Replacement of power components, ventilators, relays/auxiliaries, electro-chemical capacitors, thermal grease.

- Checks and tests:

- Of the low-level supplies (+24 + 10)

- Of the current balances on the entry phases

- Of the motor current

- Of the excitation current for CC variators

- Of the excitation regulator (deexcitation)

- Of the thyristors openings for CC variators

- Of the 4 quadrant (motor / generator) operation

- Of the closed-loop/open-loop operation

- Of the command logic

- Of the analogue reference and analogue feedback

- Of the accessibility and safeguarding of the settings on the digital variators

- Of the current reading

- Of the ventilator and turbine (rotation, noise, vibration, direction)

Following all these services, the variator underwent a 12-hour dynamic load test and counter-measuring with a robot.