43 Simovert Masterdrive drives from 0.75 kW to 700 kW

Client expectation

A manufacturer of heat-laminated steel drums based in Germany wished to back up one of its production lines. Indeed, the electrical installation of the latter, which processes the manufacture of drums with a 98% pure alloy destined for top range automobiles, had not been updated since its first commissioning, in other words for more than 15 years. Within this context, it was imperative to back up the line drivers in order to extend the life of our client’s installation over the next 10 years.

DV GROUP Solution

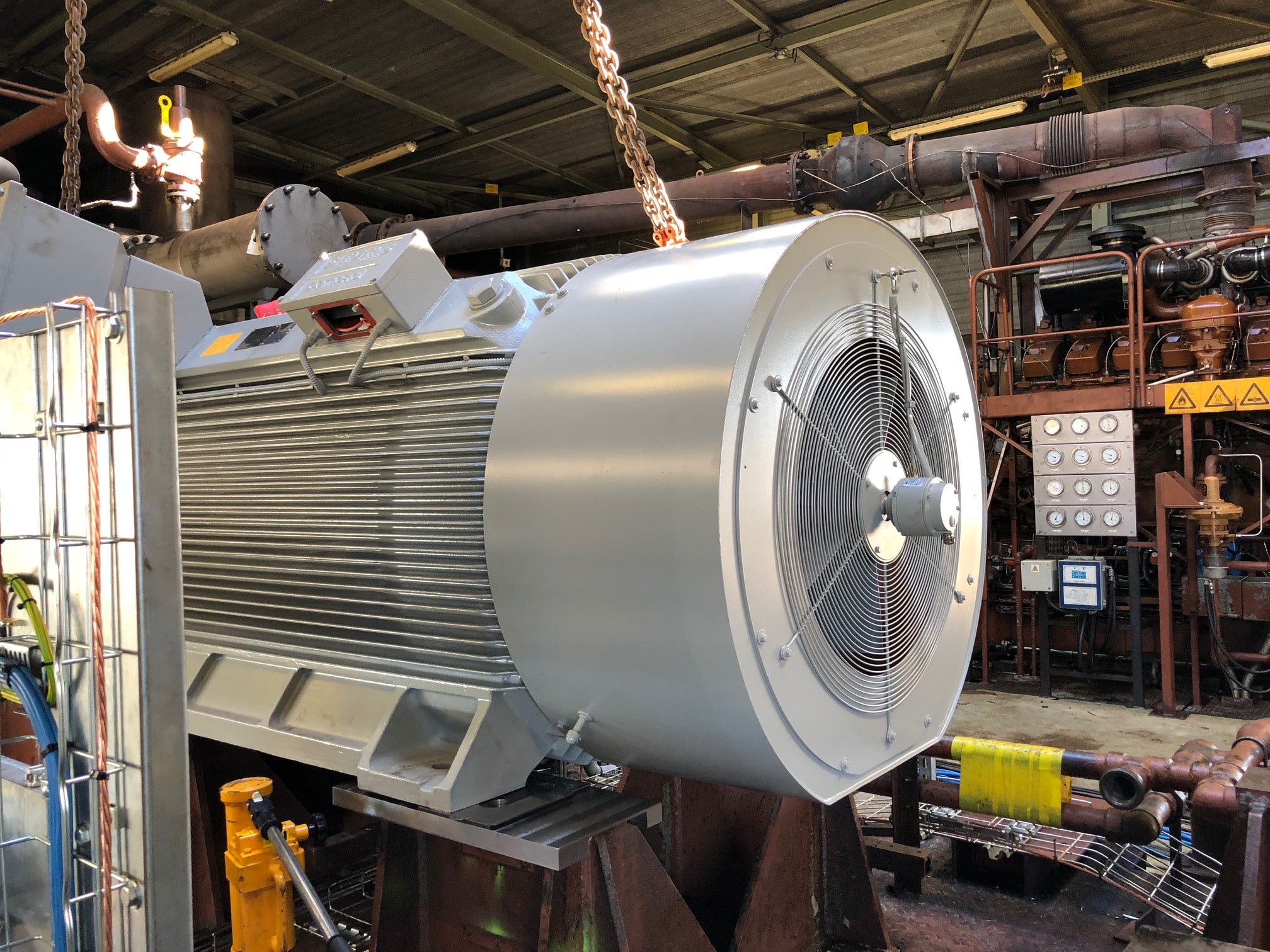

Satisfied with our quality of service during a previous emergency intervention on a 630 kW principal reinjection feed, our client entrusted us with the preventive repair of 43 Simovert Masterdrive drives from 0.75 kW to 700 kW.

So, over 8 weeks, the experts were mobilised onsite in Germany to process the products and meet the schedule imposed by our client.

Work carried out

DV GROUP technical solution:

- The dismounting and global de-polluting of all the drive components.

- Static monitoring of the power components via tracker + motor (insulation)

- Overhauling of the turbines (changing of the start-up condensators de start-up, as well as bearings)

- Monitoring of the intermediary buses on each drive (condensators deviation owing to ageing)

- Validation tests following reassembly of all the updated units

- Test for correct profibus communication between the API, the ET200 and drives

- Powering-on procedure of the installation via the process authorisations

- Successful sequential procedure of no-load testing of all the validated drives

- Full-load testing