Emergency repair on a 120KW ABB ACS800 drive

Client expectation

Our client, a leader in the manufacturing of polyethylene films, called us following two breakdowns encountered on two 120 KVA ABB ACS800 drives. Indeed, when the first one broke down at 8.00 pm, our client had immediately installed the drive they had in stock, but at 10.00 pm, that also broke down.

DV GROUP Solution

Our Technical Assistance team immediately sent an expert on site. The diagnosis revealed the failure of an IGBT module characterised by a short circuit between an output phase and the DC bus. The breakdown was identical on both drives. In order to allow our client to restart as quickly as possible, we dismantled the drive on site and brought both defective products back to the workshop in order to carry out an emergency repair.

Work carried out

- Full disassembly of the drive

- Replacement of the IGBT module from DV GROUP stock

- Repair of the IGD card

- Preventive maintenance of the product (upgrading of the electronic cards, replacement of the turbine bearings, cleaning)

- Load test

Our experts worked all night in order to refurbish one of the drives, so our client was able to restart his production line at 8.00 am that morning.

The drive taken from stock was also repaired over the next two days.

Expertisen

Wir bieten Ihnen Lösungen in den Bereichen Engineering, Maintenance und Control, die mit der Kenntnis Ihrer Prozesse verbunden sind.

Fallstudien

Das könnte Sie interessieren

Präventivmaßnahmen an 2 Masterdrives (800 kW, Schrank mit 3 Türen)

Notfallreparatur eines Extrudermotors (200 kW) nach einer Schwingungsmessung

Plan zur vorbeugenden Wartung von Large Drive-Antrieben

Schwingungsüberwachung einer Kaffeeproduktionsanlage

Obsoleszenzmanagement: Prüfung des Materialbestands einer Fabrik für LKW-Motoren

Reparatur und Zuverlässigkeit von Antrieben

ELOPAK: Korrigierende vorbeugende elektronische Wartung

Präventive Maintenance von Siemens Masterdrive

Sicherstellung der Zuverlässigkeit von 32 Siemens (6SE70) Masterdrives in einer Papierfabrik

MELEGHY: Präventivwartung von 24 Siemens Powerblocks-Antrieben

Preventive maintenance contract

2 LEROY SOMER 600 kW variators

Overhaul of 12 Siemens Torque Simotics T-1FW3 motors

Preventive maintenance for 17 Siemens servomotors and drives

X-FAB : Replacement of two extractor fans

Troubleshooting of an induced draught fan

19 50 kg (2.2 kW) to 5 ton (7.2MW) motor/reducer/ventilator assemblies

Overhaul of an extruder reducer with 2 indexed output shafts

Modelling of the HTA/BT electric network

Projekt zur Verbesserung der Wartungsmethoden

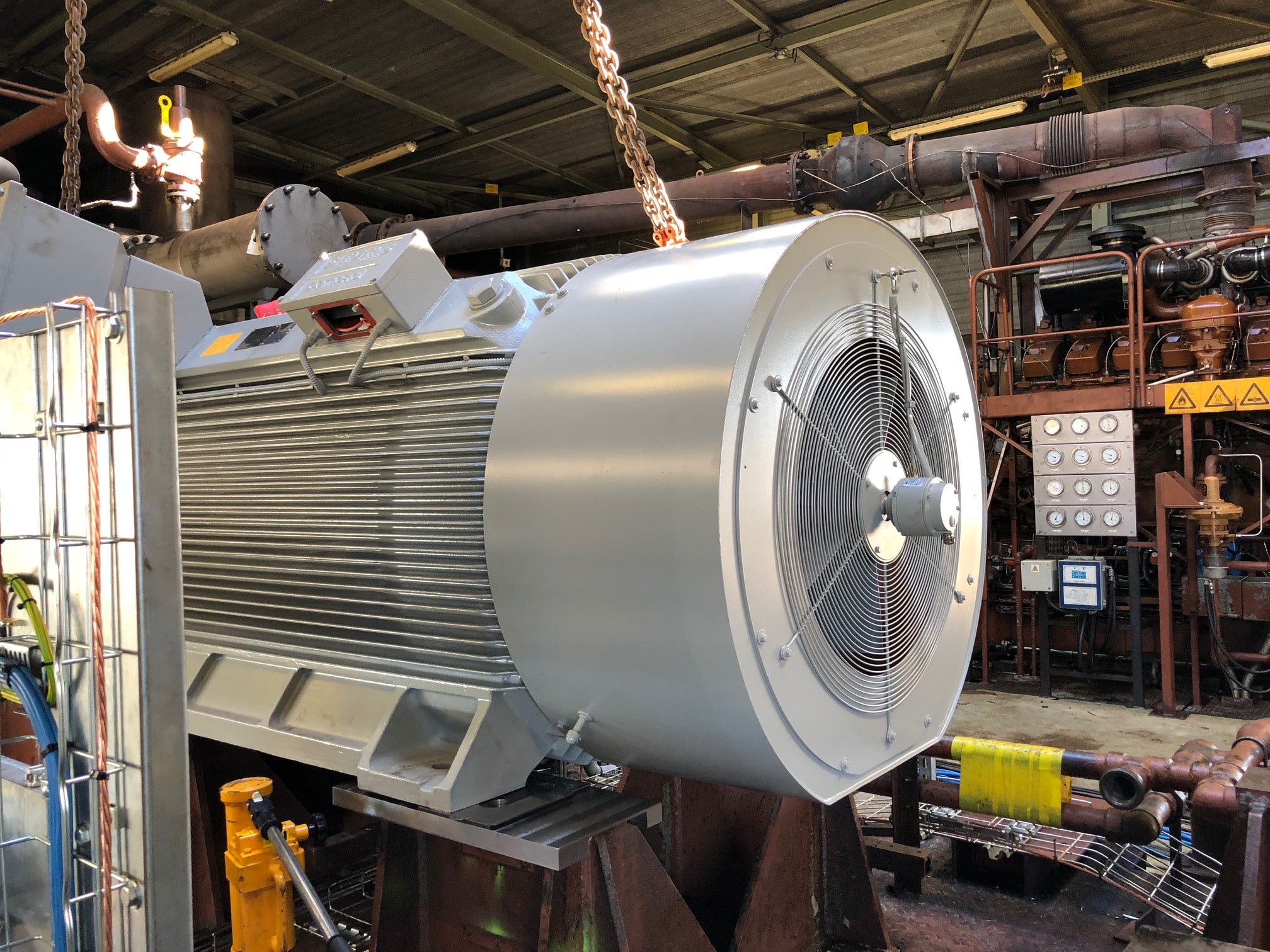

Motorisation of compressors in a colliery gas compression station

Obsolescence of the oven’s 7 CC ALSTHOM drives

Retrofitting of an impressive balancing bench

Retrofit of a machine for superfinishing machined parts

Retrofitting of the robotics part of a nine-colour printing line