Modelling of the HTA/BT electric network

Client expectation

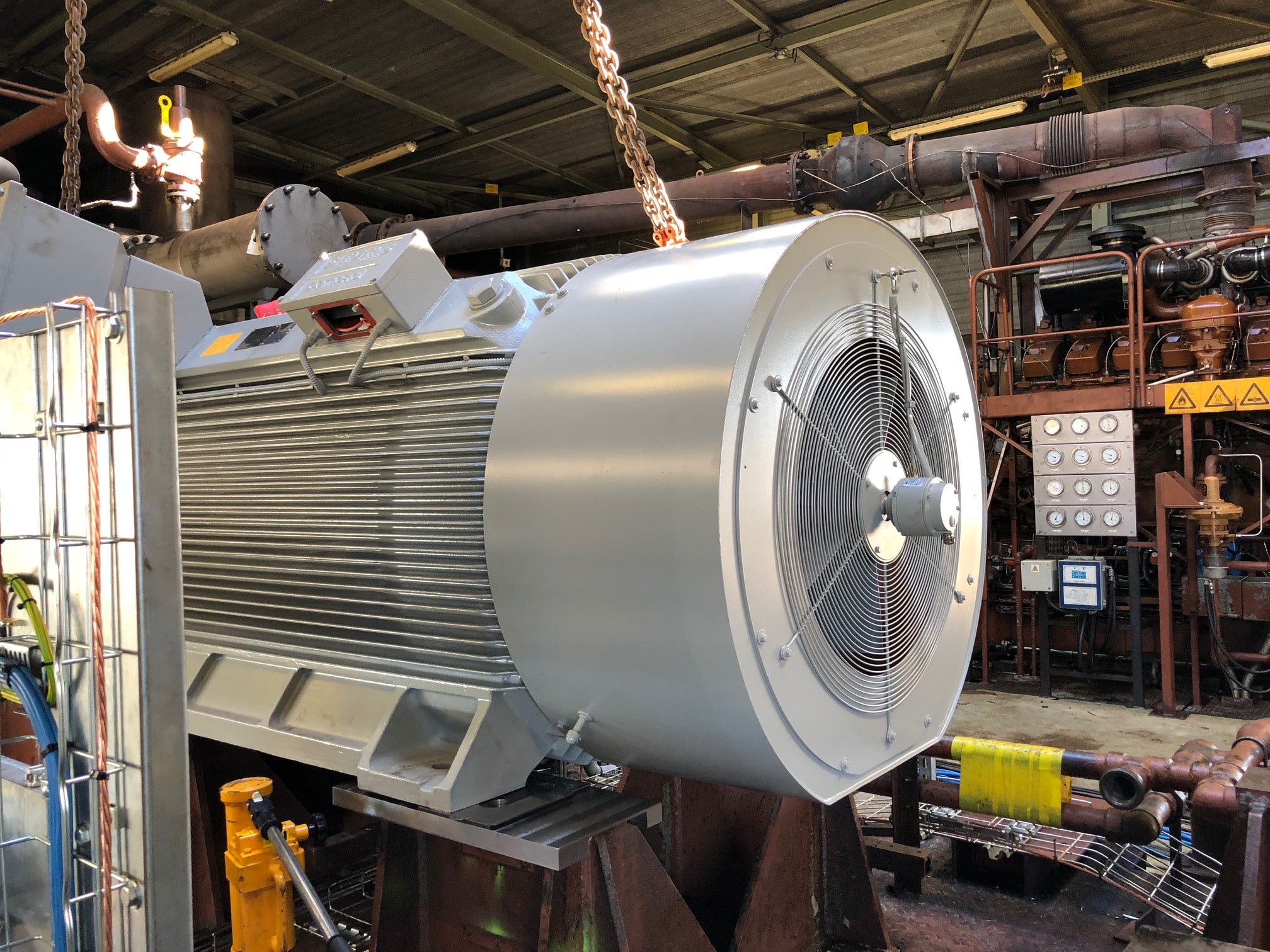

Fully committed to reducing its CO2 emissions and natural gas consumption, our client, a major player in the paper industry, commissioned a co-generation unit with a biomass boiler (production of steam and electricity) in 2019.

The client has therefore committed to a programme of investment regarding its production equipment.

The client has encountered various malfunctions of electrical origin at its site:

- Overheating of the reactive energy compensation batteries

- A breakdown of the factory’s main transformer owing to the destruction of HTB partition transverses

- Faults encountered on various speed drives

In this context, our client wished to:

- Identify the constraints of the whole site’s HTA and BT electrical distribution network

- Identify the influences of additions or modifications to the charge profiles according to projects.

DV GROUP solution

We suggested our client proceed with the analysis and modelling of the HTA/BT electrical distribution networks (including the influence of the co-generation project) and to support it in its future investments (modelling of the electrical network and studies of the functional limits in the presence of new equipment).

PHASE 1

Distribution network:

- Analysis of the modification of the topology of equipment in place (HTA condensator batteries)

- Study of the influence of harmonic currents and losses dissipated by the network’s various components, synchronous machines, condensators etc.

The analysis shows resonance phenomena associated with the historical implantation of HTA condensator batteries, their nominal power and the harmonic currents generated by all the electronic speed drives installed on the site. This finding requires a second phase of measurements on the BT networks.

Co-generation project:

- Analysis and influence of harmonic current flows on the project

- Analysis of the optimal reactive energy compensation to be implemented on the HTA network

Co-generation comprises a steam power turbine and a synchronous machine. The production performances on the HTA electrical network depend on the quality of the harmonic flow current circulating around the network. Harmonic currents impair the machine’s performance level up to 10 %.The aim of these evaluations is to connect the co-generation unit to a “healthy” electrical network.

PHASE 2

- Analysis of the various scenarios on the evolution of the network

- Monitoring of the distortion levels in the electrical network harmonics (THD-U and THD-I)

- Condition of line charges and transformers

- Establish traceability of the current quality

- Client support on its future investments

- Integration of future projects

- Study of functional limits on the network in the presence of new charge

The aim is to stimulate various operational scenarios to anticipate any malfunction (constraints at injection point, resonance, decommissioning of the machine, current stability) and the impact of synchronous machine transitory phases (current dips, phase asymmetry).

The analysis has allowed the technical specifications of the active filters and reactive energy compensation batteries to be determined and put in place onsite.

Equipment used

- DRANETZ HDPQ electrical network analysers (qualimetre) (sampling up to 1 micro second per incident)

- DRAN-VIEW 7 software for visualising and analysing data

- POWER FACTORY software and modules appropriate for modelling