Reduce and understand your energy consumption with SMART ENERGY

Number of project hours: 385 H

Project duration: 8 months

Number of technicians: 4

Customer expectations

Against a backdrop of sharply rising energy costs (electricity and gas), our customer, a specialist in the manufacture of primary parts and sub-assemblies for metal aerostructures, is looking to :

- Reduce its energy consumption

- Inform and raise staff awareness of energy issues

- Measure the cost of energy in the manufacture of parts in order to justify price increases to its customers

- Improve the energy management of its production equipment

- Gain a better understanding of the energy consumption of its various production facilities so as to prioritise investments to improve the energy efficiency of its industrial site

- Feed raw metering data back into the group.

DV GROUP solution

To deal with its energy problems, we offer a solution for monitoring its gas and electricity consumption:

- IND IT 134 CEE preliminary study

- System for measuring energy performance indicators

- Electrical studies and work (metering equipment)

- Industrial IT studies (functional specification, parameterisation, commissioning)

- Staff training

- Technical assistance service

Work completed:

We integrated our vertical ![]() with a TMA (Third Party Application Maintenance) solution to ensure maintainability (updates, recovery guarantee) and a TSA (Third Party Application Monitoring) solution to ensure monitoring. TSA involves creating alerts and notifications in relation to thresholds defined with our customer, or creating energy reports.

with a TMA (Third Party Application Maintenance) solution to ensure maintainability (updates, recovery guarantee) and a TSA (Third Party Application Monitoring) solution to ensure monitoring. TSA involves creating alerts and notifications in relation to thresholds defined with our customer, or creating energy reports.

Thanks to CEE subsidies, the project cost our customer just €1.

Our SMART ENERGY solution includes

- Training and technical assistance for the customer

- Implementation of energy monitoring software

- Training and technical support for the customer

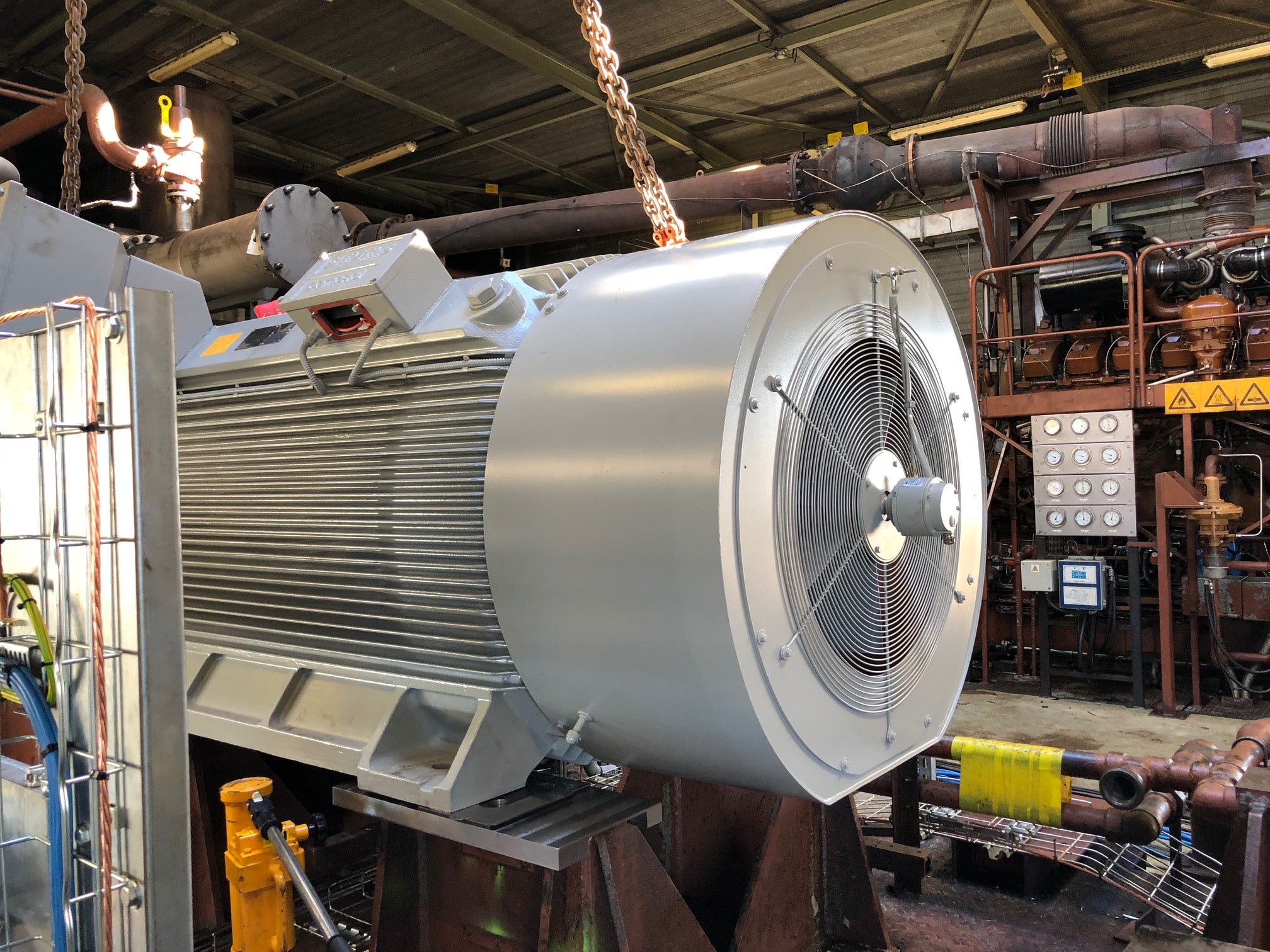

- The definition and implementation of energy efficiency solutions for its main equipment (rotary printing presses), based on our customer’s “energy map”.

- Financing the project through the IND UT 134 CEE scheme

Equipment used :

- Energy metering sensors (73 electricity, gas and compressed air metering points) communicating by radio (LoRaWAN standard)

- Interface with production management software (ERP) to retrieve data on production orders (manufactured parts)

- Smart Energy energy management software.

Customer benefits

- Expected energy savings: 4 to 8%.

- Solution at €1

- ROI of less than 1 year and more than €1 million for the duration of the contract (6 years)

- Real-time, accurate knowledge of consumption levels

- Knowledge of energy performance indicators (KWh/part produced) and the energy costs associated with each type of part produced.

- Acquisition of metering information from sensors and machines

- Real-time processing of flows (calculations and rules)

- Interfaces with production management software (ERP) and energy suppliers (electricity, gas, etc.)

- Availability of results in the form of graphs and energy performance indicators Alerting users to abnormal consumption levels

- Help in using energy data

- Initial feedback on other customer gains by the end of Q1 2024

- Prioritisation of future investments